Radio-Controlled Hay Lift Retrieves Round Bales

"It takes the work out of handling round bales," says James Rohr, North Lawrence, Ohio, who uses a radio transmitter similar to the ones used on ordinary garage door openers to build a radio¨controlled round bale "hay lift" inside his barn.

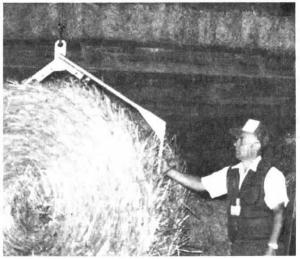

Rohr's hay lift consists of a single phase, 2-way, 1/2-hp electric motor mounted on a worm drive gearbox that's bolted to a hoist, a radio control box also bolted to the hoist, a winch, and a 3-ft. long, two-pronged bale hook that looks like ice block tongs. The hay lift winch rides on a home-built trolley system along a track in the peak of his 80 by 36 ft. barn. Rohr wears a radio transmitter around his neck. He pushes a button on the transmitter to activate relays inside the control box which power the electric motor. The motor operates the gearbox which causes the hoist to raise or lower the cable on the winch. Rohr pulls the bale lift trolleys back and forth along the track using a rope pull system.

"I built this bale lift when I switched from small bales to round bales," says Rohr. "I didn't want to store round bales outside or have to use a tractor every time I handled them." Rohr uses a skid steer loader to stack round bales three high on their ends. The hay lift can then be used to finish stacking the bales, six high up to the barn peak. The stacking process is a two-man job. One man hooks bales loaded on a wagon at the center of the barn floor. Another man working in the mow then uses the radio transmitter to raise the bale to the top of the stack. "I've never had a bale come loose from the hay lift. The prongs are hinged in the middle, so the heavier the bale, the tighter the hooks pull together."

Rohr feeds bales by lowering them to the barn floor, then rolling them by hand on top of sloping planks through the barn door and onto a catwalk leading to a round bale feeder. The bales drop right into the feeder.

Rohr bought the motor, radio control box, and radio transmitter from a local electrical supply shop. He bought the gear reduction hoist, which was equipped with the gearbox and a 3-phase electric motor, from a feed mill that used it to lift a railroad bridge. He removed the 3-phase motor and replaced it with the single-phase motor. The motor is bolted to the gearbox and the gearbox is bolted to the hoist frame. A safety light mounted onto the hoist improves visibility in the mow. The electric motor is powered by a 70-ft. long extension cord. A counter-weight keeps tension on the cord. Excess cord is dropped next to a post in the center of the barn.

Rohr spent $250 to build the hay lift - $150 for the electric motor and radio control transmitter, and $100 for the gear reduction hoist.

Contact: FARM SHOW Followup, James Rohr, 5088 Deerfield Ave., No. Lawrence, Ohio 44666 (ph 216 684-2632).

Click here to download page story appeared in.

Click here to read entire issue

Radio-Controlled Hay Lift Retrieves Round Bales CROP STORAGE Handling Equipment 14-1-11 "It takes the work out of handling round bales," says James Rohr, North Lawrence, Ohio, who uses a radio transmitter similar to the ones used on ordinary garage door openers to build a radio¨controlled round bale "hay lift" inside his barn.

Rohr's hay lift consists of a single phase, 2-way, 1/2-hp electric motor mounted on a worm drive gearbox that's bolted to a hoist, a radio control box also bolted to the hoist, a winch, and a 3-ft. long, two-pronged bale hook that looks like ice block tongs. The hay lift winch rides on a home-built trolley system along a track in the peak of his 80 by 36 ft. barn. Rohr wears a radio transmitter around his neck. He pushes a button on the transmitter to activate relays inside the control box which power the electric motor. The motor operates the gearbox which causes the hoist to raise or lower the cable on the winch. Rohr pulls the bale lift trolleys back and forth along the track using a rope pull system.

"I built this bale lift when I switched from small bales to round bales," says Rohr. "I didn't want to store round bales outside or have to use a tractor every time I handled them." Rohr uses a skid steer loader to stack round bales three high on their ends. The hay lift can then be used to finish stacking the bales, six high up to the barn peak. The stacking process is a two-man job. One man hooks bales loaded on a wagon at the center of the barn floor. Another man working in the mow then uses the radio transmitter to raise the bale to the top of the stack. "I've never had a bale come loose from the hay lift. The prongs are hinged in the middle, so the heavier the bale, the tighter the hooks pull together."

Rohr feeds bales by lowering them to the barn floor, then rolling them by hand on top of sloping planks through the barn door and onto a catwalk leading to a round bale feeder. The bales drop right into the feeder.

Rohr bought the motor, radio control box, and radio transmitter from a local electrical supply shop. He bought the gear reduction hoist, which was equipped with the gearbox and a 3-phase electric motor, from a feed mill that used it to lift a railroad bridge. He removed the 3-phase motor and replaced it with the single-phase motor. The motor is bolted to the gearbox and the gearbox is bolted to the hoist frame. A safety light mounted onto the hoist improves visibility in the mow. The electric motor is powered by a 70-ft. long extension cord. A counter-weight keeps tension on the cord. Excess cord is dropped next to a post in the center of the barn.

Rohr spent $250 to build the hay lift - $150 for the electric motor and radio control transmitter, and $100 for the gear reduction hoist.

Contact: FARM SHOW Followup, James Rohr, 5088 Deerfield Ave., No. Lawrence, Ohio 44666 (ph 216 684-2632).

To read the rest of this story, download this issue below or click

here to register with your account number.