Self Propelled Cultivator Made From Old Combine

✖  |

"My home-built 8-row self-propelled cultivator, made from a junked out early 1970's International 315 combine, has better visibility and maneuverability than any tractor-cultivator combination on the market," says William Augustine, Rose Hill, Iowa.

The 2-WD machine, which pushes a rear-mount Noble cultivator, is equipped with a band sprayer during cultivation. Augustine can replace the cultivator with a broadcast spray boom, wick wiper or a hay mower that he made from an old soybean header.

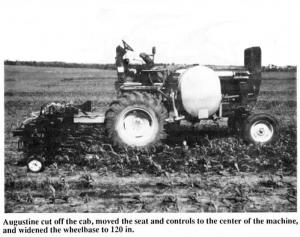

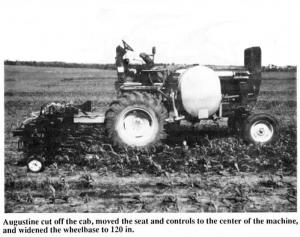

"I built this machine because I didn't like the poor visibility with rear mounted cultivators," says Augustine, who built the self-propelled cultivator a year ago. "During cultivation I use spray nozzles to deliver a 10-in. wide band of herbicide which costs only about one third as much per acre as broadcasting. The 400-gal. saddle tanks are mounted behind the driver's seat where they can't block the view like tractor-mounted saddle tanks do. Also, the driver's seat and controls are centered above the eight rows so I have a good view of weeds coming up. The narrow 16.9 by 26 tires fit more easily between my 30-in. rows than conventional tractor tires do. The best part is that I paid less than $1,000 to build this rig.

Augustine bought the combine for $300 at a farm sale. It had a worn out threshing mechanism and a 40 hp, 6-cylinder gas engine that had recently been overhauled. The first step was to strip off the threshing mechanism and build a new frame out of 3 by 8-in. box beam steel for the engine and hydrostatic transmission in order to lower the center of gravity of the machine. Next he cut off the cab and moved the seat and controls to the center of the machine. He widened the axles to 120 in. allowing the rig to straddle four rows, and shortened the wheelbase 2 ft. allowing tighter turns. He then made U-clamps to bolt steel arms to the cultivator toolbar. The arms attach the cultivator to the combine's original header mounting brackets. The 15-ft. broadcast spray boom, wick wiper, and mower are also mounted to the header mounting brackets. Augustine built the mower by removing the auger and rear framework from an old bean header. Hay mowed by the header's cutterbar simply drops to the ground behind the header where it's raked into windrows.

Two cylinders fold the wings on the cultivator. There are three pumps - a hydro-static pump for the transmission, a hydraulic pump for lifting the cultivator and folding the wings, and a hydraulic pump that drives the sprayer and mower. "A hydro-static drive transmission is a must for anyone considering building a similar rig because of its easy maneuverability," notes Augustine.

For more information, contact: FARM SHOW Followup, William Augustine, RR 1, Box 157, Rose Hill, Iowa 52586 (ph 515 632-8364).

Click here to download page story appeared in.

Click here to read entire issue

Self propelled cultivator made from old combine COMBINES Conversions 13-5-25 "My home-built 8-row self-propelled cultivator, made from a junked out early 1970's International 315 combine, has better visibility and maneuverability than any tractor-cultivator combination on the market," says William Augustine, Rose Hill, Iowa.

The 2-WD machine, which pushes a rear-mount Noble cultivator, is equipped with a band sprayer during cultivation. Augustine can replace the cultivator with a broadcast spray boom, wick wiper or a hay mower that he made from an old soybean header.

"I built this machine because I didn't like the poor visibility with rear mounted cultivators," says Augustine, who built the self-propelled cultivator a year ago. "During cultivation I use spray nozzles to deliver a 10-in. wide band of herbicide which costs only about one third as much per acre as broadcasting. The 400-gal. saddle tanks are mounted behind the driver's seat where they can't block the view like tractor-mounted saddle tanks do. Also, the driver's seat and controls are centered above the eight rows so I have a good view of weeds coming up. The narrow 16.9 by 26 tires fit more easily between my 30-in. rows than conventional tractor tires do. The best part is that I paid less than $1,000 to build this rig.

Augustine bought the combine for $300 at a farm sale. It had a worn out threshing mechanism and a 40 hp, 6-cylinder gas engine that had recently been overhauled. The first step was to strip off the threshing mechanism and build a new frame out of 3 by 8-in. box beam steel for the engine and hydrostatic transmission in order to lower the center of gravity of the machine. Next he cut off the cab and moved the seat and controls to the center of the machine. He widened the axles to 120 in. allowing the rig to straddle four rows, and shortened the wheelbase 2 ft. allowing tighter turns. He then made U-clamps to bolt steel arms to the cultivator toolbar. The arms attach the cultivator to the combine's original header mounting brackets. The 15-ft. broadcast spray boom, wick wiper, and mower are also mounted to the header mounting brackets. Augustine built the mower by removing the auger and rear framework from an old bean header. Hay mowed by the header's cutterbar simply drops to the ground behind the header where it's raked into windrows.

Two cylinders fold the wings on the cultivator. There are three pumps - a hydro-static pump for the transmission, a hydraulic pump for lifting the cultivator and folding the wings, and a hydraulic pump that drives the sprayer and mower. "A hydro-static drive transmission is a must for anyone considering building a similar rig because of its easy maneuverability," notes Augustine.

For more information, contact: FARM SHOW Followup, William Augustine, RR 1, Box 157, Rose Hill, Iowa 52586 (ph 515 632-8364).

To read the rest of this story, download this issue below or click

here to register with your account number.