Auger Loader Teams Up With Vacuum Mover

"It's the slickest grain moving system we've ever seen," says Don Tucker, who along with his brothers Wayne and Gerry, have invented a new grain handling system that teams up a loader-mounted auger with a pneumatic grain handler.

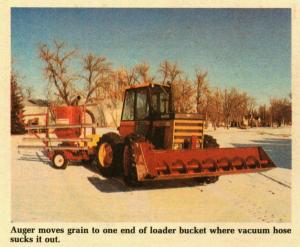

The loader-auger was designed to move grain stored inside in flat storage, or in piles outside. The auger, mounted inside a conventional tractor loader bucket, augers grain to one end of the bucket where it's sucked out by a vacuum tube attached there. The grain moves through the tube for loading into a truck, or into another auger for transfer to bin storage.

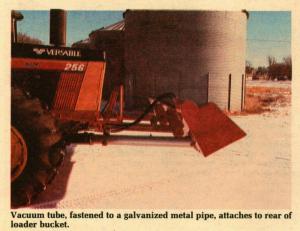

The 12-in. dia. auger mounts inside the 7 ft. wide loader bucket. A hydraulic motor mounted on the bucket and powered by auxiliary tractor hydraulics turns the auger. The 18-in. wide lip at the bottom of the bucket helps scoop up grain, and the auger pulls it to the hose at one end of the bucket. The hose runs back to the pneumatic unit, mounted on a trailer at the rear of the tractor, and to an output pipe.

The auger feeds grain to the pneumatic unit at the rate of 1,700 to 1,800 bu. per hour. It can also be used to unload grain from trucks by parking the loader bucket under the rear truck endgate and dumping grain into it. Tucker mounts the auger on a 70 hp. Versatile.

Don Tucker says he has no plans to produce the auger loader commercially.

For more information, contact: FARM SHOW Followup, Don Tucker Dakota Oat Processors, Arlington, S. Dak. 57212 (ph 605 983-5631 or 826-4103).

Click here to download page story appeared in.

Click here to read entire issue

Auger loader teams up with vacuum mover GRAIN HANDLING Miscellaneous 9-5-16 "It's the slickest grain moving system we've ever seen," says Don Tucker, who along with his brothers Wayne and Gerry, have invented a new grain handling system that teams up a loader-mounted auger with a pneumatic grain handler.

The loader-auger was designed to move grain stored inside in flat storage, or in piles outside. The auger, mounted inside a conventional tractor loader bucket, augers grain to one end of the bucket where it's sucked out by a vacuum tube attached there. The grain moves through the tube for loading into a truck, or into another auger for transfer to bin storage.

The 12-in. dia. auger mounts inside the 7 ft. wide loader bucket. A hydraulic motor mounted on the bucket and powered by auxiliary tractor hydraulics turns the auger. The 18-in. wide lip at the bottom of the bucket helps scoop up grain, and the auger pulls it to the hose at one end of the bucket. The hose runs back to the pneumatic unit, mounted on a trailer at the rear of the tractor, and to an output pipe.

The auger feeds grain to the pneumatic unit at the rate of 1,700 to 1,800 bu. per hour. It can also be used to unload grain from trucks by parking the loader bucket under the rear truck endgate and dumping grain into it. Tucker mounts the auger on a 70 hp. Versatile.

Don Tucker says he has no plans to produce the auger loader commercially.

For more information, contact: FARM SHOW Followup, Don Tucker Dakota Oat Processors, Arlington, S. Dak. 57212 (ph 605 983-5631 or 826-4103).

To read the rest of this story, download this issue below or click

here to register with your account number.