1990 - Volume #14, Issue #5, Page #31

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Bi Fold Door Has Its Own Lift Frame

|

|

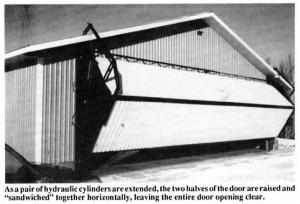

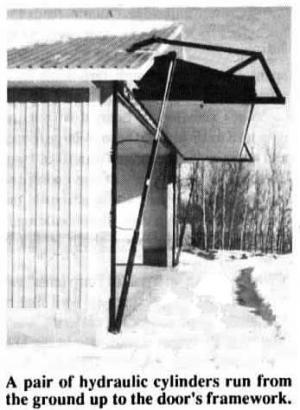

Lew Dalman says his company's patent pending bi-fold door transfers most of the forces of raising, lowering and folding the door to ground level through triangle-shaped lift frames on each end of the door. A pair of hydraulic cylinders run from the ground up to the framework. As the cylinders are ex-tended, the two halves of the door are raised and "sandwiched" together horizontally, leaving the entire door opening clear.

"Other bifold doors require a heavy, expensive header and they take up to 2 ft. of headroom because, they can't open all the way," says Dalman. "On my door vertical forces are transferred to the ground. Horizontal forces are accommodated by tying into the wall or roofline. There's no loss of headroom at all and the door is 4 in. thick so it can be insulated to R-30. Other bifold doors are limited to 2 in. thick insulation because they can't lift more weight."

According to Dalman, the door can be built to almost any width. "One farmer wants me to build a 75 ft. wide, 16-ft. high door on his machine shed. There's no reason it can't be done. The door isn't affected by wind because the double-acting cylinders automatically lock it in any position when it stops. There's no need for manual locks."

A 14 by 20-ft. door sells for about $3,600 depending on the building. You can make your own door and buy the framework in kit form.

Contact: FARM SHOW Followup, Dalman Equip. Inc., Box 261, Baldur, Manitoba, Canada R0K 0B0 (ph 204 535-2083).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.