Tool-Mounting System Makes It Easy To Move Bench-Mounted Tools Around Shop

✖  |

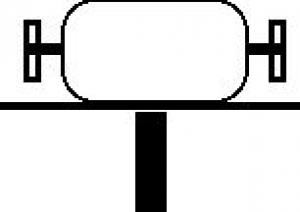

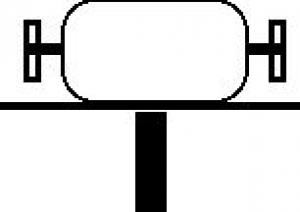

G.A. Henderson, Rt. 1, Box 264, Williamstown, W. Va. 26187 ph 304 464-4579; E-mail: gahenderson@aol.com): "I came up with a nifty tool-mounting system that makes it easy to move bench-mounted tools around the shop and also take them around the farm. This includes my drill press, chop saw, pipe vice, and regular shop vice. I bolt each tool to the top of a 1/4-in. thick metal plate and welded a short length of 1 1/2-in. dia. pipe to the bottom of the plate. I also drilled a series of holes into my steel work bench and welded 4-in. long, 2-in. dia. pipes into them, flush with the top of the pipe tool. I use a set screw to lock the two pipes together to hold the tool rigid.

"I also welded a 40-in. length of 2-in. dia. pipe into the hub of a car tire. I can turn the tire on its side and roll it around anywhere I want, then lay the tire flat and mount a tool on the pipe. I also fastened a 2-in. dia. pipe to the side of a wagon that I use to haul 20-ft. lengths of plastic irrigation pipe. I carry my portable generator and chop saw on the wagon. Once I get to the field I mount the chop saw on the side of the wagon, hook it up to the generator, and cut pipe right in the field.

"I also welded a 2-in. dia. pipe to one end of a 28-in. length of box tubing that fits into the receiver hitch on my pickup. The box tubing extends beyond the pickup tailgate when it's in the down position. The tool mounts on top of the pipe at the same level as the pickup bed."

Click here to download page story appeared in.

Click here to read entire issue

Tool-Mounting System Makes It Easy To Move Bench-Mounted Tools Around Shop FARM SHOP Tools 25-5-38 G.A. Henderson, Rt. 1, Box 264, Williamstown, W. Va. 26187 ph 304 464-4579; E-mail: gahenderson@aol.com): "I came up with a nifty tool-mounting system that makes it easy to move bench-mounted tools around the shop and also take them around the farm. This includes my drill press, chop saw, pipe vice, and regular shop vice. I bolt each tool to the top of a 1/4-in. thick metal plate and welded a short length of 1 1/2-in. dia. pipe to the bottom of the plate. I also drilled a series of holes into my steel work bench and welded 4-in. long, 2-in. dia. pipes into them, flush with the top of the pipe tool. I use a set screw to lock the two pipes together to hold the tool rigid.

"I also welded a 40-in. length of 2-in. dia. pipe into the hub of a car tire. I can turn the tire on its side and roll it around anywhere I want, then lay the tire flat and mount a tool on the pipe. I also fastened a 2-in. dia. pipe to the side of a wagon that I use to haul 20-ft. lengths of plastic irrigation pipe. I carry my portable generator and chop saw on the wagon. Once I get to the field I mount the chop saw on the side of the wagon, hook it up to the generator, and cut pipe right in the field.

"I also welded a 2-in. dia. pipe to one end of a 28-in. length of box tubing that fits into the receiver hitch on my pickup. The box tubing extends beyond the pickup tailgate when it's in the down position. The tool mounts on top of the pipe at the same level as the pickup bed."

To read the rest of this story, download this issue below or click

here to register with your account number.