2006 - Volume #30, Issue #1, Page #24

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Built-From-Scratch" Rope Maker

|

|

|

|

|

"I often demonstrate the unit at local county fairs, where it's a big hit," says the 82-year-old Willard. "Kids get to make their own 6-ft. long ropes. Adults are amazed that it'll make ropes up to 1 inch in diameter and that I can make rope from many different materials, such as plastic or hemp baler twine."

Willard says he came up with the idea after he found an old rope maker at an auction and had no idea how to use it until a friend showed him what to do. It worked, but not too well, so he decided to build his own.

"I'm so happy that I learned how to build this machine and make rope the easy way," says Willard. "I've enjoyed making improvements on this contraption and showing it off to friends and neighbors. Now I'd like to pass the idea on to others."

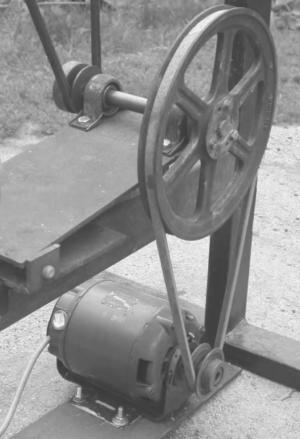

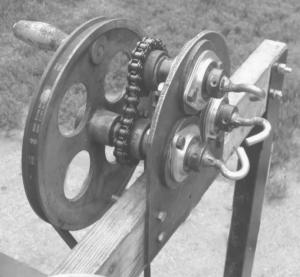

The rope maker consists of a 33-in. high, triangle-shaped metal stand equipped with three pulleys that support a weight block, and a metal stand with a small electric motor at the bottom and the rope making unit at the top. The motor belt-drives a 10-in. pulley, which in turn chain-drives three shafts mounted in flange bearings on a steel plate. A 5/16-in. hook is welded to the end of each shaft. A jackshaft located between the motor and pulley is used to slow down the speed at which the rope maker turns.

A four-pronged divider is used to keep the three twisting strands apart until they have twisted sufficiently to begin "laying by". To turn the motor on or off, Willard uses a floor switch salvaged from an old checkout counter that's wired to the motor. "I keep the switch in my left hand and a divider fork in my right hand to keep the rope tight as I go along," he says.

"I start at the weight block end of the rope and run the strands through the divider to keep the three strands apart. Then I turn on the motor and hold the divider until the three strands start getting tension. Once the ropes have twisted together, I move along toward the revolving hooks. Once the rope is completely finished I turn off the motor and then put some tape around the strings. It takes about 10 minutes to make a 6-ft. rope. The heavier the twine, the quicker the rope can be made."

The rope can be made longer by raising a pipe on the weight stand. Willard simply removes a bolt, then raises the pipe and reinserts the bolt in another hole.

"I've made ropes up to 30 ft. long. The heavier the twine, the thicker the rope. However, I think smaller twine makes the nicest rope," says Willard. "By running the rope three times I can put 18 strings into one rope. It's so strong that you can use it to pull cars out of mud holes."

You need to have a weight, such as sandbags, on the base of the weight stand so it doesn't tip over, he says.

Contact: FARM SHOW Followup, Willard Pearson, 1306 Samuelson Rd., Angora, Minn. 55703 (ph 218 666-5483).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.