1981 - Volume #5, Issue #2, Page #14

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

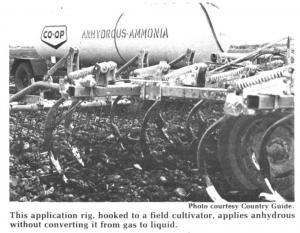

Apply Anhydrous As You Disk, Cultivate

|

Biggest advantage is that you save a trip over the field. What's more, most farmers already doing it will tell you that the two-in-one operation works great.

"I've had excellent results," reports Gordon Frew, Norwich, Ont., one of the first Canadian farmers to try the idea. Using a kit manufactured by Harlan Mfg., Harlan, Iowa, and sold in Canada by United Co-Op, of Ontario, in Mississauga, he equipped his heavy duty, 23 ft. field cultivator to apply anhydrous ammonia four years ago.

"You need a heavy field cultivator to do the job right ù a cultivator that can hold a steady 5 or 6 in. working depth," Gordon points out. "If the cultivator shanks are too light, they'll spring back and raise, permitting ammonia to escape into the air."

When he started out, it just seemed simpler to Frew to buy a heavy cultivator and pull a tank behind it, in-stead of creeping along with a conventional anhydrous applicator. He had a local machine shop make up some special injector pipes to be attached behind each of the shanks in the center row of his cultivator. A skid plate welded underneath the pipes helps prevent dirt from plugging the openings. Anhydrous flows from the tank, through a pressure regulator, and to hoses connected to each injector.

It cost Frew about $400 four years ago to equip his 23 ft. cultivator for anhydrous application. He raises 800 acres of corn and aims to have all the ground fall plowed. In the spring, he works the ground once with the cultivator as he applies anhydrous. This is followed by a disc harrow to incorporate herbicide prior to planting.

Harlan Mfg., a pioneer in developing kits for applying anhydrous with tillage implements, started with a kit for field cultivators. "We have since added complete kits for discs and chisel plows, with our disc kits now being our biggest seller," Bill Ahlers, Jr., marketing director, told FARM SHOW.

Each Harlan kit includes everything you need to make the bare implement an applicator. Harlan's hydraulic shutoff ù the An-Hydra Positrol ù and a nurse tank hitch are optional parts of the kit. Harlan also offers the DeTracker, a device for scratching out wheel tracks laid down by the nurse tank.

Here, according to Ahlers, are key features of Harlan kits for the following tillage equipment:

Field cultivators: There are two basic ways to set up a field cultivator to apply anhydrous. You can have the ammonia applied at the existing cultivator shanks with either a pipe and bracket or a replacement spike. The second method is with a 21 in. tine using a special clamp. This latter alternative is generally used when sweeps are mounted on the cultivator shanks rather than spikes. Spacing is usually 18 in. ù by either setting up one row of shanks, or placing a tine in between every shank on the rear bar of the cultivator.

Chisel plows: They are set up for anhydrous on the shanks with either a pipe and bracket, or a replacement spike. For straight chisel points, either an offset pipe or an in-line pipe can be used. A beaver tail sealer can be added to the in-line pipe to aid in sealing. Spacing on most chisels is 24 in., or every other shank, although many are set up at 12 in. on every shank.

Disc kit: It allows both spring and fall application with the same implement. Harlan mounts 3/4 in. tines behind the back gangs of the disc by adding a separate toolbar. A special swivel clamp is used to hold the tine, allowing it to pivot freely. The tine pulls straight no matter what angle you have the disc. An added feature of the Harlan clamp is its ability to hold the tine securely upside down. This makes it possible to disc without running the tines in the ground. It is a 5 min. operation to turn the tines up or down, leaving the hoses attached. Spacing of the tines on toolbars can be whatever you prefer ù 20 to 24 in. spacing has proven to be most popular. Toolbars added behind the back gangs are all

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.