Business Is Booming For "No Dirt" Gardens

Len Pense figures an acre of his gardens could yield a quarter million dollar income a year, and that's without any dirt. Pense, a retired defense department contractor, has created a Garden of Eden on a rocky piece of ground in Missouri. Now people are coming from all over the country to learn from him and buy his secret mix.

"This thing is spreading like wildfire," says Pense. "I'm shipping material to fill garden beds in California, Florida, New York and everywhere in between. It has literally exploded on me, and I have people coming to my farm by the thousands."

Pense claims he started out with the goal of being self sufficient for himself and his extended family. The trouble was his place was all rocks. Instead of hauling in soil, he developed a mix of peat moss, vermiculite, perlite, cotton burr compost and rice hulls to which he added 42 trace elements.

"It gives plants the exact balance of everything they need to explode," says Pense. "With no dirt or manure, I have no weeds, no e-coli and no salmonella to worry about. Plants always do their best in loose, well drained soil, and that's what this mix is."

Pense spreads out landscape cloth to prevent weed growth. Then he lays out 64 cinder blocks two high to form a raised garden bed that he fills with his mixture. He prefers 4 by 16-ft. beds as it makes it easy to use 16-ft. cattle panels for climbing plant support.

"The material to fill and feed a 4 by 16-ft. bed costs $417 the first year and $50 in maintenance in following years," says Pense. "It will easily grow from $1,000 to $1,500 in produce each year."

What started out as a private effort became very public when the retailer where he bought his supplies got curious. Once he saw what Pense was doing, he asked him to talk about it on a local radio show. Listeners jammed the phone lines and Pense offered to teach a class on his method. He had 67 people signed up for his first class before the show ended. Interest grew from there.

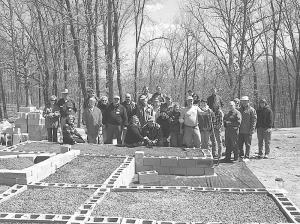

Today Pense offers classes every Saturday from January until Thanksgiving. Classes for special groups are held during the week. Attendees pay $50 each with a spouse or other family member paying half price. His website gets more than 1,000 hits a day, and he has people driving halfway across the country to see his gardens and take classes on planning with his methods. He has even built a cabin for holding classes and processing garden produce. Former students are welcome to return and participate in planting, maintenance and harvest and/or attend classes on canning produce.

Pense has also developed plant supports that serve double duty. PVC pipe provides supports for plants and for overhead sprinklers for watering. Pense hangs his cattle panel vine supports on pvc pipe on the north side of the beds, which mostly run east and west. That way when they are covered with pole beans or other climbing plants, they don't shade out other plants. Beds that are planted early or late have hoops that curve from one side of the bed to the other to provide supports for row covers.

Pense uses the holes in the cinder blocks to stabilize the pvc pipes and the hoops. Tomato plants are supported by cages up to 16 ft. tall made from concrete reinforcing panels.

He claims a single bed can produce 100 quarts of green beans. He says one of his 16-ft. tall tomato plants will produce 150 lbs. of fruit in a bad year.

The loose material in the beds has other benefits too. "When potatoes start blooming, I can reach into the beds and pull off new potatoes without disturbing the plant," says Pense. "Carrots are perfectly formed as well."

Contact: FARM SHOW Followup, Pensaroda Farm, 8389 Owls Nest Lane, Strafford, Mo. 65757 (ph 417 736-3251; fax 417 736-9861; www.gardeningrevolution.com; lenpense@gardeningrevolution.com).

Click here to download page story appeared in.

Click here to read entire issue

Business Is Booming For "No Dirt" Gardens FARM HOME Miscellaneous 31-6-33 Len Pense figures an acre of his gardens could yield a quarter million dollar income a year, and that's without any dirt. Pense, a retired defense department contractor, has created a Garden of Eden on a rocky piece of ground in Missouri. Now people are coming from all over the country to learn from him and buy his secret mix.

"This thing is spreading like wildfire," says Pense. "I'm shipping material to fill garden beds in California, Florida, New York and everywhere in between. It has literally exploded on me, and I have people coming to my farm by the thousands."

Pense claims he started out with the goal of being self sufficient for himself and his extended family. The trouble was his place was all rocks. Instead of hauling in soil, he developed a mix of peat moss, vermiculite, perlite, cotton burr compost and rice hulls to which he added 42 trace elements.

"It gives plants the exact balance of everything they need to explode," says Pense. "With no dirt or manure, I have no weeds, no e-coli and no salmonella to worry about. Plants always do their best in loose, well drained soil, and that's what this mix is."

Pense spreads out landscape cloth to prevent weed growth. Then he lays out 64 cinder blocks two high to form a raised garden bed that he fills with his mixture. He prefers 4 by 16-ft. beds as it makes it easy to use 16-ft. cattle panels for climbing plant support.

"The material to fill and feed a 4 by 16-ft. bed costs $417 the first year and $50 in maintenance in following years," says Pense. "It will easily grow from $1,000 to $1,500 in produce each year."

What started out as a private effort became very public when the retailer where he bought his supplies got curious. Once he saw what Pense was doing, he asked him to talk about it on a local radio show. Listeners jammed the phone lines and Pense offered to teach a class on his method. He had 67 people signed up for his first class before the show ended. Interest grew from there.

Today Pense offers classes every Saturday from January until Thanksgiving. Classes for special groups are held during the week. Attendees pay $50 each with a spouse or other family member paying half price. His website gets more than 1,000 hits a day, and he has people driving halfway across the country to see his gardens and take classes on planning with his methods. He has even built a cabin for holding classes and processing garden produce. Former students are welcome to return and participate in planting, maintenance and harvest and/or attend classes on canning produce.

Pense has also developed plant supports that serve double duty. PVC pipe provides supports for plants and for overhead sprinklers for watering. Pense hangs his cattle panel vine supports on pvc pipe on the north side of the beds, which mostly run east and west. That way when they are covered with pole beans or other climbing plants, they don't shade out other plants. Beds that are planted early or late have hoops that curve from one side of the bed to the other to provide supports for row covers.

Pense uses the holes in the cinder blocks to stabilize the pvc pipes and the hoops. Tomato plants are supported by cages up to 16 ft. tall made from concrete reinforcing panels.

He claims a single bed can produce 100 quarts of green beans. He says one of his 16-ft. tall tomato plants will produce 150 lbs. of fruit in a bad year.

The loose material in the beds has other benefits too. "When potatoes start blooming, I can reach into the beds and pull off new potatoes without disturbing the plant," says Pense. "Carrots are perfectly formed as well."

Contact: FARM SHOW Followup, Pensaroda Farm, 8389 Owls Nest Lane, Strafford, Mo. 65757 (ph 417 736-3251; fax 417 736-9861; www.gardeningrevolution.com; lenpense@gardeningrevolution.com).

To read the rest of this story, download this issue below or click

here to register with your account number.