1995 - Volume #19, Issue #2, Page #24

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

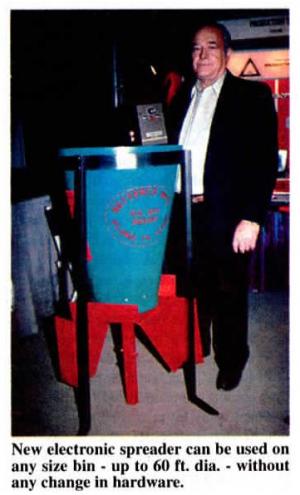

Even Spread Spreader Adjusts To Flow Of Grain

|

An electronic dial controller that mounts outside the bin is used to used to regulate the speed of a specially designed electric motor mounted inside the hopper. The motor controls how fast the wings rotate. Weights can be bolted onto the wings, al-lowing you to aim the grain at any angle you want.

"It's the easiest-to-use bin spreader on the market and also the most accurate," says Jake Donelson, inventor. "There are no belts or pulleys and no vanes to adjust. It can be used in all sizes of bins up to 60 ft. in dia. without any change in hardware. There's only adjustment on the controller - a knob that controls wing rotation speed infinitely from 0 to 120 rpm's. The automatically activated, hinge-mounted centrifugal wings raise or lower with any change in the speed of the motor.

"The amount of opening between the bottom of the hopper and the wings is con-trolled by a mechanical cam-and-spring mechanism. As grain flow increases, the cams spring open, causing the spreader assembly to lower. The motor is protected by a baffle. It's rugged - you can stall it, but it won't burn out. We offer models equipped with 1/3, 1/2, 3/4, or 1 hp motors. The 1 hp motor can handle up to 6,000 bu. per hour."

The 1 /3 hp model sells for $1,000; the 1 hp model for $1,800.

Contact: FARM SHOW Followup, Betterco Mfg., Box 860497, Plano, Texas 75086 (ph 214 424-4706).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.