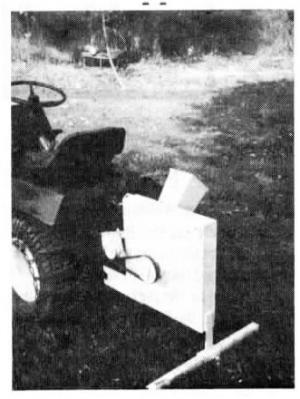

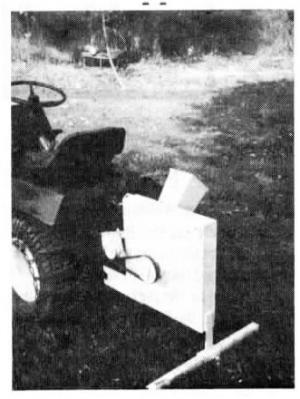

Garden Tractor Wood Chipper

✖  |

"It'll chip branches up to 4 in. in dia. and won't kill no matter how fast you feed it," says Larry Dunn, Iona Station, Ontario, who used the flywheel off an old Chevrolet 427 car engine and a 4-in. long cutter blade to build a pto-driven wood chipper that mounts behind his Allis-Chalmers 416 garden tractor.

Dunn bolted the cutter blade to the face of the flywheel and enclosed it inside a 20-in. sq. housing made from 1/4-in. thick steel plate. Chips discharge out the bottom, which is completely open. He used 3/16-in. sheet metal to make a tapered feed chute with a 4-in. sq. opening and bolted it to one side of the housing. He cut a 3/4-in. wide, 3-in. long slot in the fly-wheel to let chips pass through, then mounted the flywheel on one end of a short steel shaft. He mounted a pulley on the other end of the shaft - outside the housing - so the flywheel can be belt-driven off a gearbox at the rear of the tractor.

"It'll chip any branch that'll fit into the chute," says Dunn. "I built it because I have a lot of trees that require pruning and cutting. I had been burning the cuttings but I thought that was wasteful. I use the chips as mulch for flower beds and around trees and shrubs. Commercial units sell for $1,400. I spent only about $400 to build mine. Most commercial units have only a 5 or 6 hp engine that'll lug down on large tree limbs. My garden tractor has a 16 hp engine that operates at 3,600 rpm's. The flywheel operates at the same speed as the engine. Another advantage of my chipper is that it eliminates the need to maintain another engine.

"To operate the chipper, I use a lever to lower a spring-loaded idler pulley onto the drive belt. I use an inclined sheet of 3/ 4-in. thick plywood to deflect chips to the side. The chips fly out the bottom of the housing with so much force they chew a hole through the plywood in only two hours. If I were to build another one I'd build a steel plate onto the bottom of the housing."

Cutting a slot in the flywheel removed a lot of weight and put it off balance. Dunn mounted a bolt in the other side of the flywheel to equalize the weight. "It's best to use flywheels off old car engines because they're balanced. A lot of the flywheels on modern engines aren't balanced," notes Dunn.

Contact: FARM SHOWs. Followup, Larry Dunn, Box 4, Iona Station, Ontario, Canada N0L 1P0 (ph 519 764-2229).

Click here to download page story appeared in.

Click here to read entire issue

Garden Tractor Wood Chipper TRACTORS Accessories 18-2-12 "It'll chip branches up to 4 in. in dia. and won't kill no matter how fast you feed it," says Larry Dunn, Iona Station, Ontario, who used the flywheel off an old Chevrolet 427 car engine and a 4-in. long cutter blade to build a pto-driven wood chipper that mounts behind his Allis-Chalmers 416 garden tractor.

Dunn bolted the cutter blade to the face of the flywheel and enclosed it inside a 20-in. sq. housing made from 1/4-in. thick steel plate. Chips discharge out the bottom, which is completely open. He used 3/16-in. sheet metal to make a tapered feed chute with a 4-in. sq. opening and bolted it to one side of the housing. He cut a 3/4-in. wide, 3-in. long slot in the fly-wheel to let chips pass through, then mounted the flywheel on one end of a short steel shaft. He mounted a pulley on the other end of the shaft - outside the housing - so the flywheel can be belt-driven off a gearbox at the rear of the tractor.

"It'll chip any branch that'll fit into the chute," says Dunn. "I built it because I have a lot of trees that require pruning and cutting. I had been burning the cuttings but I thought that was wasteful. I use the chips as mulch for flower beds and around trees and shrubs. Commercial units sell for $1,400. I spent only about $400 to build mine. Most commercial units have only a 5 or 6 hp engine that'll lug down on large tree limbs. My garden tractor has a 16 hp engine that operates at 3,600 rpm's. The flywheel operates at the same speed as the engine. Another advantage of my chipper is that it eliminates the need to maintain another engine.

"To operate the chipper, I use a lever to lower a spring-loaded idler pulley onto the drive belt. I use an inclined sheet of 3/ 4-in. thick plywood to deflect chips to the side. The chips fly out the bottom of the housing with so much force they chew a hole through the plywood in only two hours. If I were to build another one I'd build a steel plate onto the bottom of the housing."

Cutting a slot in the flywheel removed a lot of weight and put it off balance. Dunn mounted a bolt in the other side of the flywheel to equalize the weight. "It's best to use flywheels off old car engines because they're balanced. A lot of the flywheels on modern engines aren't balanced," notes Dunn.

Contact: FARM SHOWs. Followup, Larry Dunn, Box 4, Iona Station, Ontario, Canada NOL 1PO (ph 519 764-2229).

To read the rest of this story, download this issue below or click

here to register with your account number.