1995 - Volume #19, Issue #5, Page #30

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

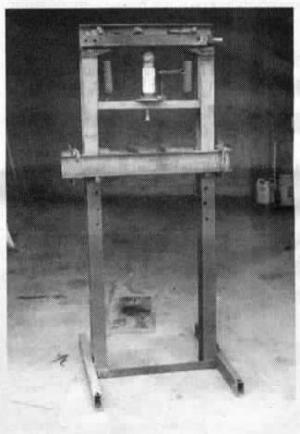

Home-Built Hydraulic Press

|

"It works as well as commercial hydraulic presses that cost $200 or more and was built entirely from salvage parts," says Freese.

He cut out sections of the stalk cutter's I-beam frame and mounted them on stands made from other parts of the frame. The press's "work table" rests on a pair of steel rods inserted through holes spaced 6 in. apart on both sides of the press frame, so the table can be moved up or down as needed. A hydraulic jack rests on a strap iron "slide" that rides up and down in-side the I-beam sides of the press. A pair of springs are used to return the jack to its closed position.

"We made it about 15 years ago and haven't found too many things it won't do," says Freese. "We use it to straighten out steel rods and shafts and to press bearings and gears on and off shafts. We even use it to straighten out bent-up beaters on manure spreaders. We have three different bottle jacks ranging from 8 to 20 tons that we use with it."

Freese welded a piece of iron across the top of the press frame to keep the sides from pushing apart.

Contact: FARM SHOW Followup, Edwin Freese, 12974 E. 23 Co. Home Rd., Scotch Grove, Iowa 52331 (ph 319 487-3651).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.