1977 - Volume #1, Issue #3, Page #16

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

New Way To Apply Anhydrous Amonia

|

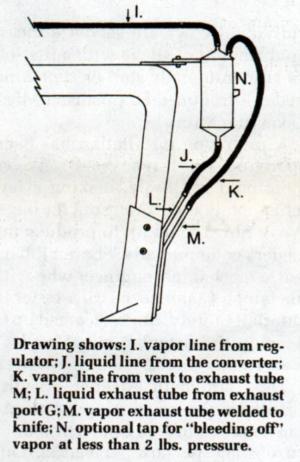

"Our units are designed to maintain a constant pressure of about 2 lbs. per sq. in.," explains Louis Siebert, owner-operator of Lou's Custom Machine Shop, Henderson, Neb. His concept for applying anhydrous as a liquid uses a converter for each row, rather than a central conversion box.

Chambers and baffles inside the cylindrical-shaped converter for each row slow down the boiling action of "hot," pressurized anhydrous as it comes out of the regulator, causing it to cool down. As it does, about 85% to 90% of it turns to liquid, and pressure is reduced to about 2 lbs. Liquid anhydrous gravity feeds from the bottom of the unit as nonpressure liquid ammonia. The remaining vapor portion comes off the top of the unit (or an optional side tap) and is also hosed into the ground.

Here, according to Siebert, is the big advantage in converting anyhydrous from "mostly gas" to "mostly liquid": "The converted anhydrous enters the soil under very little pressure. This means you don't have to knife it in as deep as with conventional application, which reduces horsepower requirements. Another key advantage is that shallower application puts the fertilizer in the root zone where it's more readily available to young, shallow-rooted plants."

Converter units adapt to chisel plows, toolbars, disks, field cultivators or whatever rig you're now using to apply conventional anhydrous ammonia. They're designed with an optional tap which can be used if less than 2 lbs. pressure is needed in certain soil conditions to prevent plugging. Virtually all the ammonia, using this tap, is converted to liquid.

Individual row converter units sell for $43, including mounting brackets, hoses and two flexible metal tubes for each shank. The tubes are flexible and can be bent as needed to conform to the shank's contour. Once bent into the proper shape, you weld them onto the shank.

For more details, contact: FARM SHOW Followup, Lou's Custom Machine Shop, Sieb Inc., Box 654, Henderson, Neb. 68371 (ph. 402 723-4468).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.