Low Pressure Nozzles Save Energy, Water

✖  |

A new low pressure nozzle promises substantial energy and water savings for irrigation farmers. Richard Malcolm, Sanger, Calif., inventor of the new-style nozzle, which operates on only 25 to 35 lbs. pressure, says water distributed by the nozzle generally covers within one to two feet of the spread of the high pressure nozzles they replace.

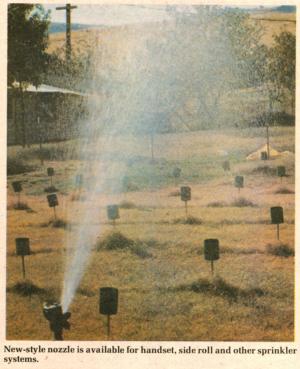

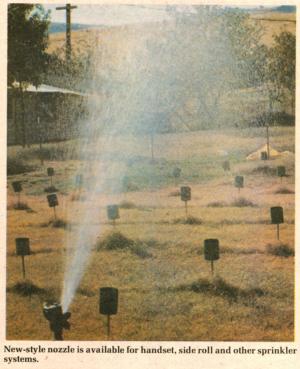

Malcolm's MG nozzle is available for handset, side roll and other sprinkler systems except center pivots. Some pivot makers and dealers, however, are experimenting with the new nozzle and results to date look promising, according to Malcolm.

The nozzle is made of a brass housing with a stainless steel insert in the center. The insert provides long wear and the specially shaped hole breaks up the stream of water mechanically instead of relying on high pressure as the industry has done for many years.

To permit operation of the same flow rate, the MG nozzle orifices are about twice as large as outlets in the standard high pressure nozzles. This has meant the reduction in nozzle plugging of 50 to 200%, and may cut irrigation labor by 25%, according to Malcolm.

He notes that, because water is not broken up as finely at low pressure, evaporation levels are much less, compared with high pressure operation. He suggests that during the hottest, driest parts of the summer, a sprinkler system converted to low pressure might deliver just as much water to the soil if it were shut off from noon to 6:00 p.m., compared to continuous operation of a high pressure system with its attendant high evaporation losses.

Malcolm cites several cases where installation of his low pressure nozzle resulted in significant savings in annual energy costs. He estimates that in California's San Joaquin Valley, it cost $1 per lb. of pressure per acre to apply irrigation water. Dropping pressure from 60 to 30 psi results in a savings about $30 per acre. But, savings in some instances have gone much higher. For instance, on 2,167 acres of wine grapes in Fresno County, Calif., switching from high pressure to low pressure costs $64,057 and provided annual energy savings of $117,677 ù about $54 per acre.

MG nozzles are being made and sold in California by MG Industries, 7108 St. Andrews, Bakersfield, Calif. 93309 (ph 805 397-8979). Distribution outside of California is being handled by Transconn Inc., John R. Beatty, manager, 2104 Stonecrest Drive, Ft. Collins, Colo. 80524 (ph 303 224-3377).

Click here to download page story appeared in.

Click here to read entire issue

Low Pressure Nozzles Save Energy, Water SPRAYING Accessories 6-4-21 A new low pressure nozzle promises substantial energy and water savings for irrigation farmers. Richard Malcolm, Sanger, Calif., inventor of the new-style nozzle, which operates on only 25 to 35 lbs. pressure, says water distributed by the nozzle generally covers within one to two feet of the spread of the high pressure nozzles they replace.

Malcolm's MG nozzle is available for handset, side roll and other sprinkler systems except center pivots. Some pivot makers and dealers, however, are experimenting with the new nozzle and results to date look promising, according to Malcolm.

The nozzle is made of a brass housing with a stainless steel insert in the center. The insert provides long wear and the specially shaped hole breaks up the stream of water mechanically instead of relying on high pressure as the industry has done for many years.

To permit operation of the same flow rate, the MG nozzle orifices are about twice as large as outlets in the standard high pressure nozzles. This has meant the reduction in nozzle plugging of 50 to 200%, and may cut irrigation labor by 25%, according to Malcolm.

He notes that, because water is not broken up as finely at low pressure, evaporation levels are much less, compared with high pressure operation. He suggests that during the hottest, driest parts of the summer, a sprinkler system converted to low pressure might deliver just as much water to the soil if it were shut off from noon to 6:00 p.m., compared to continuous operation of a high pressure system with its attendant high evaporation losses.

Malcolm cites several cases where installation of his low pressure nozzle resulted in significant savings in annual energy costs. He estimates that in California's San Joaquin Valley, it cost $1 per lb. of pressure per acre to apply irrigation water. Dropping pressure from 60 to 30 psi results in a savings about $30 per acre. But, savings in some instances have gone much higher. For instance, on 2,167 acres of wine grapes in Fresno County, Calif., switching from high pressure to low pressure costs $64,057 and provided annual energy savings of $117,677 ù about $54 per acre.

MG nozzles are being made and sold in California by MG Industries, 7108 St. Andrews, Bakersfield, Calif. 93309 (ph 805 397-8979). Distribution outside of California is being handled by Transconn Inc., John R. Beatty, manager, 2104 Stonecrest Drive, Ft. Collins, Colo. 80524 (ph 303 224-3377).

To read the rest of this story, download this issue below or click

here to register with your account number.