1990 - Volume #14, Issue #1, Page #15

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

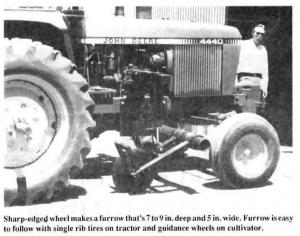

Tractor Mounted Guide System Runs 7-9 Inches Deep

|

Bernard designed and now manufactures the new system, which uses sharp-edged wheels to make the deep furrows. "I built it because we weren't happy with other systems on the market. Other systems use the weight of 3-pt. mounted implements to dig a furrow. This system uses the weight of the tractor and forms a deep, distinct furrow that'll stand up to heavy rain and irrigation. Guidance systems that use wand-type sensors require lots of electronics and can be thrown off the row if they hit a corn stalk or a dirt clod. This system makes a trench that's hard and distinct. It's the only guidance system that works well in heavy trash. The furrow is easy to follow with single rib tires on the tractor and the guidance wheels on the cultivator. Once you're in the fur-row, you can take your hands off the wheel and forget about steering."

The system consists of two wheels made up of two heavy-duty 7 ga., 20-in. dia. concave discs sandwiched together over a center plow coulter which protrudes about 1/4 in. to provide a cutting edge. Each wheel is 5 in. wide at center. The disc assemblies mount on a toolbar that runs under the tractor and bolts to the tractor frame. A pair of hydraulic cylinders raises and lowers the discs. In operation, Bernard recommends running the discs 7 to 9 in. deep so that the bearings run just above the soil surface. Discs are mounted on breakaway mountings for protection from rocks or other obstacles. Bernard is working on a unit with hydraulic bypass to provide automatic reset for use under rocky conditions.

Bernard built the first prototype 3 years ago while working as a farmhand in the Red River Valley. "I realized it was a market-able idea after the first time I took it to the field. When other farmers began to approach me to build one for them, I decided to go into business."

He formed a corporation with several partners and contracted with a manufacturer to build the units. He's been selling them for the past two seasons. The first year he sold 7 systems. Last season he sold 47.

The system itself is built heavy, weighing about 1,000 lbs. It includes two 3-in. dia. hydraulic cylinders. "Everything is built extra heavy to stand up to the weight of the tractor," says Bernard.

The under-tractor mounting system is designed for 3-pt. mounted planters. With pull-type planters, the wheel assemblies mount directly on the planter toolbar so no under-tractor frame is needed. For cultivating and other chores, the wheel assemblies are simply switched to the tillage toolbars.

Bernard says the system allows 50% higher speeds when cultivating and makes it possible for inexperienced help to do the job well. "It also lets you reduce chemical rates when banding the row. Instead of setting spray patterns 7 to 9-in. wide, you can make them 4 to 5-in. wide."

The under-tractor system sells for $3,500. If you use a pull-type planter, you'll need only the breakaway wheel assemblies for mounting on the toolbar. They sell for $816.

Contact: FARM SHOW Followup, Bernard-Hensch, Inc., Rt. 1, Box 58, Tintah, Minn. 56583 (ph toll-free 800 648-0506, or 218 369-2458).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.