1980 - Volume #4, Issue #1, Page #05

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Air-Powered Car First Of Its Kind

|

The car's designer, Terry Miller, of Crestline, Kan., built the car in 16 weeks. "With improvements, and some research into windmillpowered air compressors, its performance and economy could be amazing," states Miller, who is helping air-power enthusiasts at his own expense by giving away complete do it-yourself plans to anyone interested. He explains: "I want to see the idea developed. All I ask is a $10 royalty for any cars sold commercially."

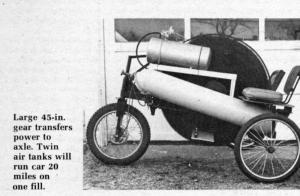

Thirty days after the car was introduced last fall, a manufacturer in nearby Riverton, Kan., had already begun gearing up to produce a commercial model. Meanwhile, a local machine shop began stamping out the large 45-in. gear which is at the center of the car's drive system.

Miller spent just $884 to build his car, which actually works something like an air compressor in reverse. Air at 2250 psi is let out of the storage tank, reduced by a regulator to 210 psi and fed into an actuating cylinder where it moves a piston attached to a crankshaft, just as exploding gasoline expands against pistons in an internal combustion engine.

The key to Miller's car, and what makes it different from attempts in the past to power vehicles with air, is his pressure equalization valve. It passes air from the first cylinder, which is now at a lower pressure, to a second piston of a different size, where 90% of the pressure is recovered and used over.

The crankshaft drives a large 45-in. main gear mounted at the center of the vehicle and that; in turn, transfers power to the 4-in. axle gear. Nearly all the parts are available from hardware stores, welding supply stores or farm supply outlets. The car has motorcycle and heavy-duty bicycle wheels, and seats two.

What power does the experimental unit have?

"We pulled a 1/2 ton pickup down the road," says Miller, but adds that "I can't really forsee the day when tractors and other farm equipment would be powered by air. The requirements are simply too great." He sees the car as an errand vehicle, or possibly a commuter car in the cities.

Miller built himself a 2-stage air compressor for $600 to compress the air, but says a commercial model capable of high pressures would cost around $2000. At current prices, he says his car costs him 1 1/2 cents a mile to run. With two air tanks mounted on the car - a total of 660 cu. ft. - he can travel close to 20 mi.

"One amazing thing - this is the only car in the world that you can drive under water. There's no air intake and only air is exhausted," he points out.

You can send for free do-it-yourself engineering plans from Miller, complete with instructions on where to buy required parts. He'll also provide information on those now gearing up to manufacture the car.

For more details, send 25 cents (for postage) along with your inquiry to: FARM SHOW Followup, Terry Miller, Air Car, Box 80, Crestline, Kan. 66728 (ph 316 389-2299).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.