1985 - Volume #9, Issue #5, Page #21

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

In Field Straw Chopper Mulches Between Rows

|

|

"It'll boost yields anywhere water run-off is a problem, trapping moisture in the row," says Hobson, who began applying straw between rows in fields years ago when he still had kids at home to help, and lots of willing neighbors. When labor became hard to find, he built his machine.

"I originally put straw between rows to improve water retention on sloping irrigated ground. We found that we not only got greatly improved yields due to the use of straw but that it did a great job helping to stop soil erosion," says Hobson.

His machine spreads straw at the rate of about 800 lbs. - 15 to 20 straw bales ù per acre, the rate recommended by researchers at the USDA Snake River Conservation Research Center, Kimberly, Idaho. Preliminary results of one study being conducted by Dr. Mel Brown at the Kimberly station indicate that one bean field, with a slope of 1.3% and no straw, yielded 42 bu. per acre while a similar field with straw between rows produced a yield of 51 bu. per acre. Another bean field, with 4.5% slope, produced 32 bu. per acre without straw and 51 bu. per acre with straw in between its rows. A third field with a 1.5% slope yielded 45 bu. per acre without straw and 54 bu. per acre with straw.

Herb Futter, conservationist with the Ontario, Oregon Soil Conservation Service, had a chance recently to observe Hobson's straw-mulched fields. "Irrigation water running through the strawed furrows is pretty clean, while that from bare furrows is muddy," he notes, adding that the SCS is encouraging farmers to try straw within the rows.

Soil conservation is just an added benefit, according to Hobson. "The primary benefit is that it boosts crop yields by improving the water absorption rate of the soil. Water movement is slowed so the ground has more time to soak it up."

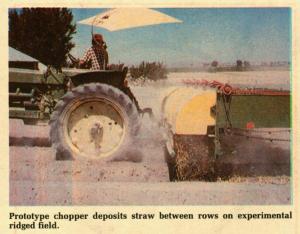

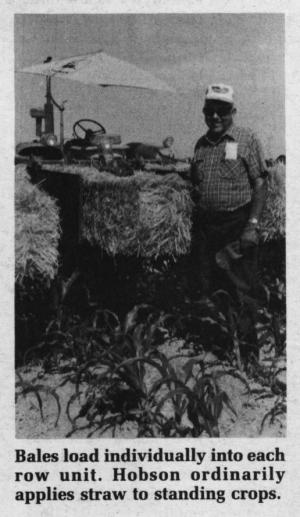

The machine consists of a series of individual bale-width size units that mount on a 2 1/2-in. diamond toolbar. The units are modularized so that you can mount as few or as many units as needed. A driveshaft powered by tractor hydraulics runs a "beater" on each unit that peels straw off the bales. The bale chamber behind the beater is long enough to hold about 1¢ bales so a new bale can be fed in as each previous bale is used up. A drag chain pulls each bale forward.

Hobson mounts the bale mulcher on the back of his cultivator and shreds straw into the rows as he does his last cultivation. In 36-in. spaced corn, for instance, he mulches a 12-in. band of straw down the center directly over the irrigation furrow. The width and thickness of the straw layer can be varied by varying tractor ground speed.

"In gardens or vegetable plots you can lay a thick enough layer of straw to stop weeds," says Hobson, noting that, according to his patent search, his machine is the first ever to mechanically mulch row crops.

The bale mulcher must be loaded by hand. Hobson parks one or two wagons around the field, depending on the size of the area to be covered. He says the length of the bale chambers behind each unit could be lengthened to hold more bales and thus cover more ground.

"Right now this machine does thework of 12 to 13 people putting straw between rows by hand," he notes.

Hobson's had interest in his prototype from all over the country, especially from researchers and farmers trying to improve water uptake on irrigation ground. Center pivot irrigators often have trouble at the outer ends of the pivot, he notes, due to the stronger flow of water. Several California researchers who have been applying straw to rows by hand have already put in an order for one of the first production units.

"But we think it'll be worthwhile anywhere that water absorption is a problem, irrigated or not," notes Hobson.

Several companies have expressed interest in manufacturing the bale mulcher. Hobson says that if he cannot work out a deal with a manufacturer, he plans to begin producing machines on his farm next winter. For more information, contact: FARM SHOW Followup. Joe Hobson Rt 1, Box 610 Ontario, Ore. 97914 (ph. 503-889-5019).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.