He Made Rubber Tracks To Fit His Deere Combine

✖  |

"It helped me get through wet conditions last fall with no problems," says Mel Gerber, Versailles, Mo., who equipped his Deere 4400 combine with 9-ft. 10-in. long Cater-pillar rubber tracks that he mounted on a home-built undercarriage.

Gerber paid $1,000 apiece for the used belts which he bought from another farmer who had been testing the 24 1/2-in. wide prototypes for Caterpillar. He mounted the belts over a pair of used semi-tractor tires that he bolted on in place of the combine's original wheels.

He then removed the combine's final drives and transmission, replacing them with a dual hydrostatic drive system. A hydraulic pump and motor are used to power the drive wheel on each track. He steers by varying oil flow to the pumps.

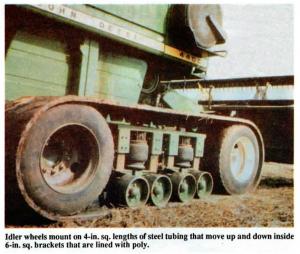

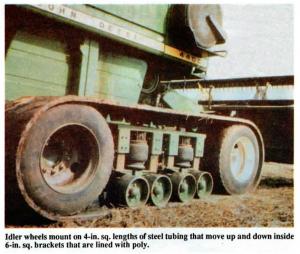

Between the two main wheels, Gerber built a flexible suspension system that al-lows the belts to "walk" over terraces without overcentering or tipping. A pair of truck air springs mount above the four idler wheels. The air springs absorb shocks as the idler wheels work their way over obstacles or uneven terrain.

Idler wheels mount on 4-in. sq. steel tubes that move up or down inside 6-in. sq. steel tubes as they flex up or down. The 6-in. sq. steel tubes are lined with poly so there's no metal-to-metal wear.

"I used the tracks for about 250 hours last fall. They worked great," says Gerber. "I also used them to harvest wheat last summer in wet ground. The suspension system lets me drive over terraces like a wheeled rig without tipping overcenter. It also applies more uniform pressure on the ground. The tracks apply only 4 1/2 psi. to the ground when fully loaded. Conventional tractor tires apply 12 to 13 psi.

"I cut off the lugs on the belts to make it easier to turn, but turning is still a problem because the tracks are so long that they scoop a lot of dirt when turning. However, this fall I plan to put more air pressure in the springs to try to solve the problem.

"I spent about $24,000 to mount the tracks on my 6-row combine. Eventually I'd like to adapt them to a bigger combine, but I wanted to try it first on a small model to see if it would work."

Gerber says he's willing to custom-build combine-mounted tracks for other farmers.

Contact: FARM SHOW Followup, Mel Gerber, Rt. 1, Box 156, Versailles, Mo. 65084 (ph 314 378-6923).

Click here to download page story appeared in.

Click here to read entire issue

He Made Rubber Tracks To Fit His Deere Combine TRACTORS Accessories 17-6-24 "It helped me get through wet conditions last fall with no problems," says Mel Gerber, Versailles, Mo., who equipped his Deere 4400 combine with 9-ft. 10-in. long Cater-pillar rubber tracks that he mounted on a home-built undercarriage.

Gerber paid $1,000 apiece for the used belts which he bought from another farmer who had been testing the 24 1/2-in. wide prototypes for Caterpillar. He mounted the belts over a pair of used semi-tractor tires that he bolted on in place of the combine's original wheels.

He then removed the combine's final drives and transmission, replacing them with a dual hydrostatic drive system. A hydraulic pump and motor are used to power the drive wheel on each track. He steers by varying oil flow to the pumps.

Between the two main wheels, Gerber built a flexible suspension system that al-lows the belts to "walk" over terraces without overcentering or tipping. A pair of truck air springs mount above the four idler wheels. The air springs absorb shocks as the idler wheels work their way over obstacles or uneven terrain.

Idler wheels mount on 4-in. sq. steel tubes that move up or down inside 6-in. sq. steel tubes as they flex up or down. The 6-in. sq. steel tubes are lined with poly so there's no metal-to-metal wear.

"I used the tracks for about 250 hours last fall. They worked great," says Gerber. "I also used them to harvest wheat last summer in wet ground. The suspension system lets me drive over terraces like a wheeled rig without tipping overcenter. It also applies more uniform pressure on the ground. The tracks apply only 4 1/2 psi. to the ground when fully loaded. Conventional tractor tires apply 12 to 13 psi.

"I cut off the lugs on the belts to make it easier to turn, but turning is still a problem because the tracks are so long that they scoop a lot of dirt when turning. However, this fall I plan to put more air pressure in the springs to try to solve the problem.

"I spent about $24,000 to mount the tracks on my 6-row combine. Eventually I'd like to adapt them to a bigger combine, but I wanted to try it first on a small model to see if it would work."

Gerber says he's willing to custom-build combine-mounted tracks for other farmers.

Contact: FARM SHOW Followup, Mel Gerber, Rt. 1, Box 156, Versailles, Mo. 65084 (ph 314 378-6923).

To read the rest of this story, download this issue below or click

here to register with your account number.