1986 - Volume #10, Issue #4, Page #07

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

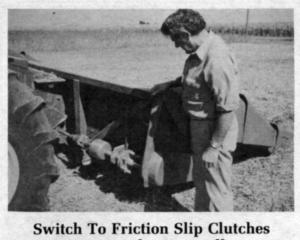

Switch To Friction Slip Clutches On Deere Header Pays Off

|

"When a ratchet clutch let's loose, it shakes the whole combine, and tears things up. I once tore up a new chain in the first half hour. And it's worse the older a header gets," notes Friedman. "Since I changed over to friction clutches, I've never had to replace a chain."

The two friction-type slip clutches Friedman installed were originally designed for a 72-in. Woods rotary mower. Unable to find used ones, he bought them new 5 years ago at $250 each. "You could use smaller slip clutches if you can find them," he points out.

To install the clutches, he first bolted the original ratchet clutches solid, then cut the shaft and installed both halves of the Woods clutch. "I use only 4 of the original 6 bolts in the Woods clutch, and I run them with as little tension as possible," he notes.

In the photo, the bell-shaped housing has been pulled aside to show how the clutch halves are bolted solid.

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.