Build Yourself A Foam House

✖  |

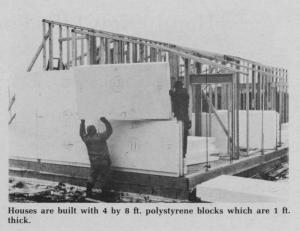

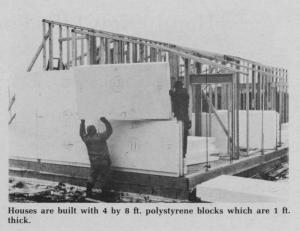

A foam house? It sounds crazy but not to Don Peterson, a McFarland, Wis., builder and designer of houses built with 4-ft. by 8-ft. by 1-ft. thick, polystyrene blocks (similar to styrofoam) and then coated with Insul-Crete ù a mixture of six components that include styrofoam, fiberglass, and Portland cement.

"The advantages of a foam house over conventional houses are lower heating, cooling and maintenance costs. The building is also more soundproof, fireproof and you'll receive lower insurance rates because of its resistance to fire," Peterson reports. "It's virtually impossible to distinguish a foam house from any other house, from the inside or outside, and there's no formaldehyde in the foam to give off dangerous fumes."

"There are many possible agricultural uses for the foam buildings with Insul-Crete," Peterson adds. "We've had inquiries about building fish hatcheries, and mushroom growing facilities. I also feel these foam buildings would make good farrowing houses and calf buildings. Foam construction allows better control of humidity and temperature.

When building the houses, the foam walls are anchored with rods to a conventional foundation. Peterson notes that he's experimenting with using foam blocks as the foundation. Insul-Crete is then poured between the blocks to "cement" them together and is also spread in a thin layer on both sides of the walls.

After the walls are up, windows and doors are cut into the blocks, and pipes and wiring put in the walls using a hotwire machine. Peterson explains that after Insul-Crete is applied, you can decorate the interior and exterior in any manner, including paneling and wallpapering.

Since the walls are actually built of insulation, you can heat inexpensively depending on the house size, climate and other factors. The 1,000 sq. ft. model home built in Wisconsin was heated for $100 a year.

The special construction also lets you use smaller heating and cooling systems. Unlike conventionally built homes though, you may need an air exchanger to bring in outside air and expel inside air.

The roof is also made of polystyrene foam. For skeptics, doubting the foam houses' strength, Peterson put a 7 1/2 ton truck on the roof and left it for 3 days.

Peterson also piled furnishings in the house and set them on fire. The fire burned out from the lack of oxygen when the doors and windows were closed. With the doors and windows left open, the furnishings burned and the fire reached temperatures of 1,700? but the only damage to the structure was blackened walls in some areas.

Peterson has blueprints available for a number of home styles. He says the cost for a foam house would be comparable to a well-built, well-insulated house.

For more information, contact: FARM SHOW Followup, Don Peterson, 4307 Triangle Street, McFarland, Wis. 53558 (ph 608 838-8023).

Click here to download page story appeared in.

Click here to read entire issue

Build Yourself A Foam House FARM HOME Houses 7-5-31 A foam house? It sounds crazy but not to Don Peterson, a McFarland, Wis., builder and designer of houses built with 4-ft. by 8-ft. by 1-ft. thick, polystyrene blocks (similar to styrofoam) and then coated with Insul-Crete ù a mixture of six components that include styrofoam, fiberglass, and Portland cement.

"The advantages of a foam house over conventional houses are lower heating, cooling and maintenance costs. The building is also more soundproof, fireproof and you'll receive lower insurance rates because of its resistance to fire," Peterson reports. "It's virtually impossible to distinguish a foam house from any other house, from the inside or outside, and there's no formaldehyde in the foam to give off dangerous fumes."

"There are many possible agricultural uses for the foam buildings with Insul-Crete," Peterson adds. "We've had inquiries about building fish hatcheries, and mushroom growing facilities. I also feel these foam buildings would make good farrowing houses and calf buildings. Foam construction allows better control of humidity and temperature.

When building the houses, the foam walls are anchored with rods to a conventional foundation. Peterson notes that he's experimenting with using foam blocks as the foundation. Insul-Crete is then poured between the blocks to "cement" them together and is also spread in a thin layer on both sides of the walls.

After the walls are up, windows and doors are cut into the blocks, and pipes and wiring put in the walls using a hotwire machine. Peterson explains that after Insul-Crete is applied, you can decorate the interior and exterior in any manner, including paneling and wallpapering.

Since the walls are actually built of insulation, you can heat inexpensively depending on the house size, climate and other factors. The 1,000 sq. ft. model home built in Wisconsin was heated for $100 a year.

The special construction also lets you use smaller heating and cooling systems. Unlike conventionally built homes though, you may need an air exchanger to bring in outside air and expel inside air.

The roof is also made of polystyrene foam. For skeptics, doubting the foam houses' strength, Peterson put a 7 1/2 ton truck on the roof and left it for 3 days.

Peterson also piled furnishings in the house and set them on fire. The fire burned out from the lack of oxygen when the doors and windows were closed. With the doors and windows left open, the furnishings burned and the fire reached temperatures of 1,700? but the only damage to the structure was blackened walls in some areas.

Peterson has blueprints available for a number of home styles. He says the cost for a foam house would be comparable to a well-built, well-insulated house.

For more information, contact: FARM SHOW Followup, Don Peterson, 4307 Triangle Street, McFarland, Wis. 53558 (ph 608 838-8023).

To read the rest of this story, download this issue below or click

here to register with your account number.