1978 - Volume #2, Issue #3, Page #20

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

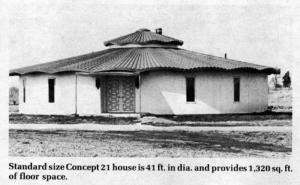

Round Fiberglass House

|

That's all changed with the arrival of the fiberglass round house that's factory pre-built and erected on your own building site. The house, with its 21st Century look, is produced by a Missouri-based manufacturer called Concept Twenty-One, Inc.

Besides its different appearance, the round fiberglass house has a number of other appeals.

1. No maintenance. Once the house is erected, it requires no painting and very little upkeep. The fiberglass shell resists most every kind of weather in every locality, says the manufacturer.

2. Fast construction. The pre-built molded fiberglass panels can be erected on your footing or foundation in one or two days, allowing all further construction to be completed, regardless of the weather.

3. Economical heating and cooling. Heating and cooling costs are "half to two-thirds of those in conventional houses" because fiberglass has low heat conductivity.

4. Rodent and termite proof.

5. Wind and weather resistant. There are no shingles to blow off, or paint to be damaged by hail. Dome shape gives low wind resistance and wind noise. Snow slides off smooth surfaced roof.

Most important, the Concept 21 house reportedly is more economical to build than most conventional houses. Finished costs run from $2 to $5 per square foot lower than the standard "stick built" or manufactured houses. It complies with most government building codes and regulations, such as Federal Housing Authority and Building Officials and Code Administrators (BOLA).

The Concept 21 design has been developed over the last 8 years at the company's headquarters in Hannibal, Mo., and is now being marketed in 12 states. It's offered in several sizes and can be built with or without basement; carports and garages can be added.

A standard size is 41 ft. in dia. which consists of 16 panels and gives 1,320 sq. ft. of floor space. The smallest model is 36 ft. irA dia. with 1,017 sq. ft., and the largest has a 56-ft. dia. and 2,463 sq. ft.

The 41-ft. model has a price tag of about $10,500. Concrete work, doors, windows, interior finish, and set-up charges have to be added to this cost of the basic walls, roof and center support structure.

Erection procedures are fast and efficient. You order the design and prepare the concrete slab or footings on your building site. The panels are made in the factory and delivered to the site within 3 to 12 weeks. You may order wood grain, stucco, smooth, or stipple finish on the wall panels. The roof has the texture of Spanish tile.

The inner walls have traditional wood studs spaced on 16 in, centers. This allows for insulating and finishing walls in a conventional way.

Most any floor pan, and heating and air conditioning systems, are adaptable to the house. The manufacturer says you can get 14% better utilization of space in a round house than in a rectangular one.

How are round fiberglass houses being accepted among farm families?

Concept Twenty-One vice president Mary Phelps says, "We have sold a lot of them on farms as veil as in cities. In fact. we have found [arm families more willing to accept this different housing concept than city people have been."

For more details, contact: FARM SHOW Followup, Fiberglass Concept 21, 400 S. 11th St., Hannibal. Mo. 63401. (ph, 314 221-4020).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.