Corn-Burning Furnace Built For $300

✖  |

"I wanted a free-standing floor furnace and I didn't see anything on the market that I liked. I also thought I could build a more efficient heat exchanger than any on the market. And I did," says Kansas farmer Ira Eichman about his home-built corn-burning furnace. It was first featured in FARM SHOW's Vol. 18, No. 6.

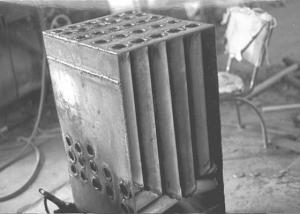

Eichman's furnace is 20 in. long by 14 in. wide by 24 in. tall. Made out of 3/16-in. thick sheet steel, the furnace is the sole source of heat for his 1,100-sq. ft. one-story farm home.

The furnace kicks out about 100,000 btu's an hour, Eichman estimates.

The heart of the system is Eichman's heat exchanger which is made out of a system of 2-in. dia. pipes mounted in a rectangular frame. "I've got a partition between the combustion chamber and the outside chamber so heat goes up the inside of the pipes and circulates, then cool air comes down the outside of the pipes," Eichman says. "It's all self-circulating, not forced air, which makes it different from any commercial corn-burning furnaces I looked at." Heat rises from the basement to the home's main floor through floor vents.

Eichman's burner is an 8-in. square box made of 1/4-in. thick stainless steel with holes drilled in the bottom. A 2-in. dia. electric fan blows air into the burner, while a 2-in. dia. flex auger with a variable speed drive, housed in a piece of 2 1/4-in. dia. car exhaust pipe, delivers corn from a hopper and gravity feeds it to the fire. Both fan and auger can be controlled from upstairs.

Eichman's grain hopper, made out of an old hog feeder, holds up to 40 bu. of corn, enough to last two or three months in the coldest part of winter. During more moderate weather, Eichman only needs 20 bu. of corn at a time to last several weeks.

For convenient cleaning, Eichman's furnace features a removable floor plate underneath the heat exchanger. "I clean it out once a year, in the fall, before I start using it," he says.

Although Eichman doesn't know exactly how efficient his furnace is, he does have one good gauge. "I use 4-in. dia. plastic sewer pipe for an exhaust pipe," he says. "I've used the furnace three years and the pipe's still like new, so that should tell you how much heat escapes. That pipe isn't made to withstand high temperatures."

Eichman burns between 100 and 120 bu. of corn per heating season, compared with the old 60,000 btu propane furnace that used to use at least 800 gal. at 16 cents a gal. "One year, I heated with moldy corn, so that didn't cost anything," he says.

The most expensive component of Eichman's furnace was the gear reduction motor he bought for $203 to run the auger. "There were cheaper ways to go," he says, "but I wanted it to last."

Contact: FARM SHOW Followup, Ira Eichman, R.R. 2, Westphalia, Kan. 66093 (ph 913 489-2386).

Click here to download page story appeared in.

Click here to read entire issue

Corn-Burning Furnace Built For $300 ENERGY Corn Burning Soves 25-2-6 "I wanted a free-standing floor furnace and I didn't see anything on the market that I liked. I also thought I could build a more efficient heat exchanger than any on the market. And I did," says Kansas farmer Ira Eichman about his home-built corn-burning furnace. It was first featured in FARM SHOW's Vol. 18, No. 6.

Eichman's furnace is 20 in. long by 14 in. wide by 24 in. tall. Made out of 3/16-in. thick sheet steel, the furnace is the sole source of heat for his 1,100-sq. ft. one-story farm home.

The furnace kicks out about 100,000 btu's an hour, Eichman estimates.

The heart of the system is Eichman's heat exchanger which is made out of a system of 2-in. dia. pipes mounted in a rectangular frame. "I've got a partition between the combustion chamber and the outside chamber so heat goes up the inside of the pipes and circulates, then cool air comes down the outside of the pipes," Eichman says. "It's all self-circulating, not forced air, which makes it different from any commercial corn-burning furnaces I looked at." Heat rises from the basement to the home's main floor through floor vents.

Eichman's burner is an 8-in. square box made of 1/4-in. thick stainless steel with holes drilled in the bottom. A 2-in. dia. electric fan blows air into the burner, while a 2-in. dia. flex auger with a variable speed drive, housed in a piece of 2 1/4-in. dia. car exhaust pipe, delivers corn from a hopper and gravity feeds it to the fire. Both fan and auger can be controlled from upstairs.

Eichman's grain hopper, made out of an old hog feeder, holds up to 40 bu. of corn, enough to last two or three months in the coldest part of winter. During more moderate weather, Eichman only needs 20 bu. of corn at a time to last several weeks.

For convenient cleaning, Eichman's furnace features a removable floor plate underneath the heat exchanger. "I clean it out once a year, in the fall, before I start using it," he says.

Although Eichman doesn't know exactly how efficient his furnace is, he does have one good gauge. "I use 4-in. dia. plastic sewer pipe for an exhaust pipe," he says. "I've used the furnace three years and the pipe's still like new, so that should tell you how much heat escapes. That pipe isn't made to withstand high temperatures."

Eichman burns between 100 and 120 bu. of corn per heating season, compared with the old 60,000 btu propane furnace that used to use at least 800 gal. at 16 cents a gal. "One year, I heated with moldy corn, so that didn't cost anything," he says.

The most expensive component of Eichman's furnace was the gear reduction motor he bought for $203 to run the auger. "There were cheaper ways to go," he says, "but I wanted it to last."

Contact: FARM SHOW Followup, Ira Eichman, R.R. 2, Westphalia, Kan. 66093 (ph 913 489-2386).

To read the rest of this story, download this issue below or click

here to register with your account number.