1990 - Volume #14, Issue #2, Page #36

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Low-Cost Straw Bale Barn

|

|

Weathering seems to be minimal. Tightly packed flax bales tied with plastic twine have proved most durable.

Charged electric fence wires attached by insulators are effective in keeping livestock away. Better yet are strong, moveable gates.

So far, no straw buildings have burned, even though operators have used tractors to clean or do inside repair.

Here's a look at several straw barns now in use throughout North Dakota:

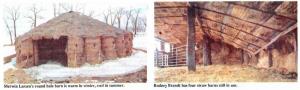

Merwin Larsen, Flaxton: He constructed a round barn for dairy heifers with round flax straw bales in 1987. Rafters were

made from two used oilfield drillstem pipes (2.8 in. dia. by 31 ft. long) welded into an A-frame. The 6 ft. wide rafter base rests atop the wall. The point is attached to an anchor ring at the top of the center pole.

The barn is 44 ft. across, with 12 ft. high walls. A woven wire inside liner is tied through the bales to outside wire bands. Estimated cost: About $500 for the pipe.

Larson says the building is not only the warmest one on his farm in winter, but the coolest in summer.

Rodney Brandt, Maxbass: Rodney, one of the first livestock producers to try straw bale barns, built a 30 by 60 by 12 ft. structure in 1984. It still functions as a cattle shelter. His newest building is a 30 by 40 ft. pole straw barn. Poles are spaced 10 ft. off center in the walls and 15 ft. through the center to support oilfield drillstem pipe rafters (2.375 in. dia.) 5 ft. apart.

Brandt, who has four straw barns still in use, has tried different straw types. He feels flax straw is the best.

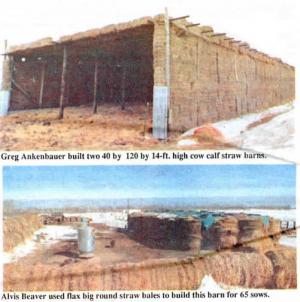

Greg Ankenbauer, Kenmare: He used conventional (18 by 18 in. by 3 ft.) flax straw bales set on edge to build cow-calf barns at two ranches in 1987. The 40 ft. wide barns have roof supports poles 8 ft. off center that support 2.8 in. dia. oilfield drill-stem pipe rafters. No. 9 ga. reinforced mesh wire was used in the roof and over the walls. Out-of-pocket cost: $1,000 for mesh and pipe in one barn. Poles, straw, twine and construction labor were on hand.

Alvis Beaver, Rolette: Alvis made a 28 by 84 by 12 ft. barn for 65 sows out of cattail-sloughgrass-kochia bales in the fall of 1988. The barn is centered over an automatic waterer divider to serve four pens. Each pen has a small doorway to an outside feedyard.

Alvis spaced used 35 ft. electric poles 3 ft. apart for rafters. They rest on a 2 by 10 in. plate atop the walls.

Pigs preferred the cattail bales. Estimated cost: About $900 for the poles. Other materials were on hand and the Beaver family supplied the labor.

Arden Moline, Rugby: He notes that sheep ate through and over a snow fence in a 32 by 48 ft. barn he made of 6 by 4 ft. round bales.

Moline spent $100 for poles, door framing and three balls of plastic baler twine for the barn in 1987. He stretched woven wire and stapled it to electric pole rafters spaced from 4 to 6 ft. apart.

Straw-barn owners report that disease, bird and rodent problems in straw barns are similar to conventional buildings containing feed, bedding and insulation.

(Reprinted from The Farmer magazine)

The author is professor emeritus at North Dakota State University. While there is no formal research project at NDSU, straw bale buildings will continue to be monitored informally to determine optimum roof slope, construction design, straw type, bale protection and rafter design. Dexter would like to hear from FARM SHOW readers who have had experience with straw-bale buildings. Contact:FARM SHOW Followup, Dexter W. Johnson, PE, Agricultural Engineer, 1237 3rd Street North, Fargo, N. Dak. 58102 (ph 701 232-2915).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.