Air-Operated Cutter Cuts O-Rings

✖  |

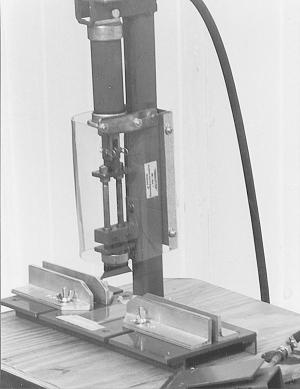

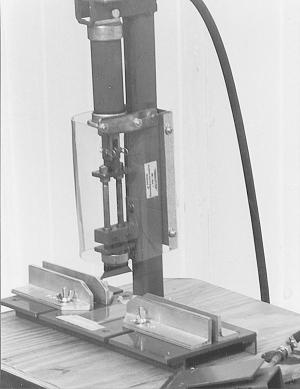

T.E. Salsman, Richmond, Ky.: "My son-in-law operates Circle Seal & Gasket, a company that makes custom-sized O-rings for various industries. O-ring material is cut to precision length and the ends joined by a heat process. As the company has been in business for only about a year, close management of operating costs is mandatory. At first they used a hand-operated cutter to cut all raw material, but it's a tiring, labor-intensive operation. There was nothing on the market that could do the job at a price they could justify.

"So I started developing an air-operated cutter. As it turns out, my crude prototype has been in daily use for months and has cut material for several thousand O-rings. My billed cost for parts in building it was only $55.

"The cutter operates at about 90 lbs. air pressure and drives a 1 1/2-in. air cylinder with a 2-in. stroke. The push rods are two grade 5 bolts that operate through bronze bushings (replaceable at Ace Hardware store for $1.49 each). The cutterhead, which has a 1/8-in. key fixed in place with JB Weld, drives a Stanley commercial grade box knife blade. The cutterhead is controlled by a 1-in. shaft with 1/8-in. keyways at 30, 45, and 90 degrees, to cut the material as required by the type splice for that particular O-ring. Moveable guides keep the material aligned for cutting.

"I'm now looking for a source of knives which will increase the tool's cutting capability."

Click here to download page story appeared in.

Click here to read entire issue

Air-Operated Cutter Cuts O-Rings FARM SHOP Tools 26-3-38 T.E. Salsman, Richmond, Ky.: "My son-in-law operates Circle Seal & Gasket, a company that makes custom-sized O-rings for various industries. O-ring material is cut to precision length and the ends joined by a heat process. As the company has been in business for only about a year, close management of operating costs is mandatory. At first they used a hand-operated cutter to cut all raw material, but it's a tiring, labor-intensive operation. There was nothing on the market that could do the job at a price they could justify.

"So I started developing an air-operated cutter. As it turns out, my crude prototype has been in daily use for months and has cut material for several thousand O-rings. My billed cost for parts in building it was only $55.

"The cutter operates at about 90 lbs. air pressure and drives a 1 1/2-in. air cylinder with a 2-in. stroke. The push rods are two grade 5 bolts that operate through bronze bushings (replaceable at Ace Hardware store for $1.49 each). The cutterhead, which has a 1/8-in. key fixed in place with JB Weld, drives a Stanley commercial grade box knife blade. The cutterhead is controlled by a 1-in. shaft with 1/8-in. keyways at 30, 45, and 90 degrees, to cut the material as required by the type splice for that particular O-ring. Moveable guides keep the material aligned for cutting.

"I'm now looking for a source of knives which will increase the tool's cutting capability."

To read the rest of this story, download this issue below or click

here to register with your account number.