Idler Pulley Repair Saves Farmers $640

✖  |

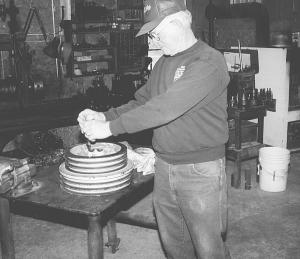

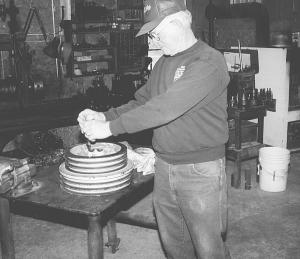

Dale Denton, Cowden, Ill., is a retired machinist with a well-equipped country shop. He has a reputation for being able to rebuild expensive farm equipment parts for a lot less than new. One of his most cost-effective repairs is the way he rebuilds the main idler pulley on older New Holland combines. New pulleys cost about $700 but he rebuilds the old ones for only about $60.

Denton bores out the old pulley and puts in a new sleeve so he can install the original size bearing.

Contact: FARM SHOW Followup, Dale Denton, RR 1, P.O. Box 168, Cowden, Ill. 62422 (ph 217 783-6530).

Click here to download page story appeared in.

Click here to read entire issue

Idler Pulley Repair Saves Farmers $640 FARM SHOP Repairs 31-4-38 Dale Denton, Cowden, Ill., is a retired machinist with a well-equipped country shop. He has a reputation for being able to rebuild expensive farm equipment parts for a lot less than new. One of his most cost-effective repairs is the way he rebuilds the main idler pulley on older New Holland combines. New pulleys cost about $700 but he rebuilds the old ones for only about $60.

Denton bores out the old pulley and puts in a new sleeve so he can install the original size bearing.

Contact: FARM SHOW Followup, Dale Denton, RR 1, P.O. Box 168, Cowden, Ill. 62422 (ph 217 783-6530).

To read the rest of this story, download this issue below or click

here to register with your account number.