2009 - Volume #33, Issue #3, Page #37

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Modified Drill Bits Fit Worn Chucks

|

"As a chuck ages, it's hard for it to hold a bit when it hits resistance," says Gibbs. "I found out that it helps to grind flat faces on the drill bit ends."

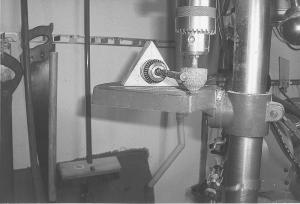

To get three even faces, Gibbs has come up with a simple jig. He cuts a triangle with 4-in. sides from a piece of 2-in. thick scrap wood. An old chuck is then mounted in the triangle's center and an emery wheel mounted on Gibbs' drill press.

"I mount the drill bit with the cutting end in the chuck and slide it against an emery wheel on my drill press," explains Gibbs. "When I have a slight face on one side, I just turn the wood block to the next side and slide it back to the emery wheel."

Contact: FARM SHOW Followup, Joe Gibbs, 1115 Club Meadows Drive, Columbia, Mo. 65203 (ph 573 818-0347).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.