PTO Drive Unit For A Belt Powered

✖  |

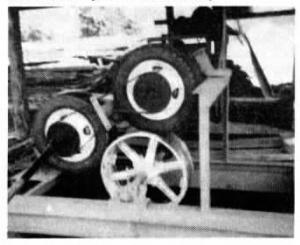

I designed this drive unit for a belt-powered sawmill several years ago and have sawed over 150,000 ft. of wood with no problems at all. !was looking for something that would be easier to use than a flat belt because they would always run off the pulley and had to be so carefully lined up. I wanted to use the same tractor for handling logs and powering the saw. Now I can change from moving logs and lumber to sawing wood in less than a minute with my Massey Ferguson 285 tractor. The tricky part in designing the drive was figuring out how much tire contact was needed to transmit the power of the 85 hp. tractor to the saw drive pulley. Two tires with 1-ton dish wheels attach to 3/4-ton axle housings mounted on a 7-ft. long 8-in. H-beam. A 48-tooth RC60 sprocket bolts to the center of each wheel. Adrive chain, held tight by an idler wheel, runs between the two sprockets.

A splined pto stub shaft is welded to the center of the lowest sprocket to hook up to the tractor pto. The tires each have about 10 psi air pressure so they'll grip the pulley. The tires heat up just enough to help them pull good. The wheel assembly hinges at the bottom so down pressure can be applied to both drive wheels with an adjusting bolt. You can't just hook up the tractor directly to the saw drive shaft because it would turn the saw backwards. My drive unit reverses the saw.

I've made five different units for neighboring farmers and they're all working fine. We did a patent search and there's nothing like it on the market. (Contact: FARM SHOW Followup, G.A. Seay, Rt. 2, Box 91, Moneta, Va. 24121 ph 703 297-5385)

Click here to download page story appeared in.

Click here to read entire issue

PTO Drive Unit for A Belt Powered WOODLOT EQUIPMENT Miscellaneous 15-5-33 I designed this drive unit for a belt-powered sawmill several years ago and have sawed over 150,000 ft. of wood with no problems at all. !was looking for something that would be easier to use than a flat belt because they would always run off the pulley and had to be so carefully lined up. I wanted to use the same tractor for handling logs and powering the saw. Now I can change from moving logs and lumber to sawing wood in less than a minute with my Massey Ferguson 285 tractor. The tricky part in designing the drive was figuring out how much tire contact was needed to transmit the power of the 85 hp. tractor to the saw drive pulley. Two tires with 1-ton dish wheels attach to 3/4-ton axle housings mounted on a 7-ft. long 8-in. H-beam. A 48-tooth RC60 sprocket bolts to the center of each wheel. Adrive chain, held tight by an idler wheel, runs between the two sprockets.

A splined pto stub shaft is welded to the center of the lowest sprocket to hook up to the tractor pto. The tires each have about 10 psi air pressure so they'll grip the pulley. The tires heat up just enough to help them pull good. The wheel assembly hinges at the bottom so down pressure can be applied to both drive wheels with an adjusting bolt. You can't just hook up the tractor directly to the saw drive shaft because it would turn the saw backwards. My drive unit reverses the saw.

I've made five different units for neighboring farmers and they're all working fine. We did a patent search and there's nothing like it on the market. (Contact: FARM SHOW Followup, G.A. Seay, Rt. 2, Box 91, Mon-eta, Va. 24121 ph 703 297-5385)

To read the rest of this story, download this issue below or click

here to register with your account number.