He Saved Money By Moving Neighbors Barn

✖  |

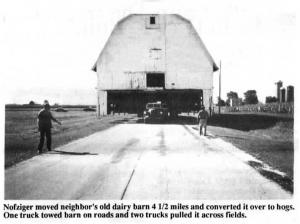

Curt Nofziger, Archbold, Ohio, wanted to put up a new hog finishing building - until he found out how much it would cost. That's when he got the cost-saving idea of buying his neighbor's old dairy barn. He moved it 4 1/2 miles and converted it over to hogs. The trek took the barn across fields, high-ways, bridges, and ditches.

"I got the barn free and in excellent condition. I was able to move it and get it into operating condition for about half the cost of putting up a new hog finishing barn. Another advantage is that it's more versatile than a specialized building. I could also use it for cattle or sheep or to store machinery."

Nofziger hired Junior Harmon from Napoleon, Ohio, to move the 40-ft. wide, 101-ft. long barn. Nofziger got the required moving permits for township, county, and state highways and contacted the local telephone company and rural electric cooperative about raising or removing lines along the barn's path. He hired two off-duty high-way patrolmen and rented two marked patrol cars to block highway traffic. He also contacted 30 landowners along the route to get permission to trim trees, pull signs, and remove mailboxes and newspaper boxes.

One truck was used to tow the barn on roads and two trucks - one equipped with a winch - were used to pull it across fields.

Harmon and crew jacked the barn up and put steel I-beams and dollies underneath. A total of 32 wheels supported the barn. A tandem hitch connected the rear sets of dollies, allowing workers to steer from the back when maneuvering barn around turns.

Harmon used a 1948 2-ton truck equipped with beefed-up springs and three transmissions to tow the barn. "The range of speeds provided by the three transmissions allows the truck to start moving very slowly. Once we were on the road, we were able to move at a fast walk," says Nofziger.

The biggest challenge was getting around a couple of trees that grow close to the road. They had to steer the barn to the side and run one set of dolly wheels in a shallow ditch. They placed timbers in the ditch to bring the dollies on that side of the barn up to road level. As the barn inched ahead, timbers were continually taken from behind the wheels and placed ahead of them.

Contact: FARM SHOW Followup, Curtis L. Nofziger, 1-24232-H, Archbold, Ohio 43502 (ph 419 445-4482).

Click here to download page story appeared in.

Click here to read entire issue

He Saved Money By Moving Neighbors Barn AG WORLD Ag World 18-3-19 Curt Nofziger, Archbold, Ohio, wanted to put up a new hog finishing building - until he found out how much it would cost. That's when he got the cost-saving idea of buying his neighbor's old dairy barn. He moved it 4 1/2 miles and converted it over to hogs. The trek took the barn across fields, high-ways, bridges, and ditches.

"I got the barn free and in excellent condition. I was able to move it and get it into operating condition for about half the cost of putting up a new hog finishing barn. Another advantage is that it's more versatile than a specialized building. I could also use it for cattle or sheep or to store machinery."

Nofziger hired Junior Harmon from Napoleon, Ohio, to move the 40-ft. wide, 101-ft. long barn. Nofziger got the required moving permits for township, county, and state highways and contacted the local telephone company and rural electric cooperative about raising or removing lines along the barn's path. He hired two off-duty high-way patrolmen and rented two marked patrol cars to block highway traffic. He also contacted 30 landowners along the route to get permission to trim trees, pull signs, and remove mailboxes and newspaper boxes.

One truck was used to tow the barn on roads and two trucks - one equipped with a winch - were used to pull it across fields.

Harmon and crew jacked the barn up and put steel I-beams and dollies underneath. A total of 32 wheels supported the barn. A tandem hitch connected the rear sets of dollies, allowing workers to steer from the back when maneuvering barn around turns.

Harmon used a 1948 2-ton truck equipped with beefed-up springs and three transmissions to tow the barn. "The range of speeds provided by the three transmissions allows the truck to start moving very slowly. Once we were on the road, we were able to move at a fast walk," says Nofziger.

The biggest challenge was getting around a couple of trees that grow close to the road. They had to steer the barn to the side and run one set of dolly wheels in a shallow ditch. They placed timbers in the ditch to bring the dollies on that side of the barn up to road level. As the barn inched ahead, timbers were continually taken from behind the wheels and placed ahead of them.

Contact: FARM SHOW Followup, Curtis L. Nofziger, 1-24232-H, Archbold, Ohio 43502 (ph 419 445-4482).

To read the rest of this story, download this issue below or click

here to register with your account number.