1979 - Volume #3, Issue #6, Page #32

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Break-Through Dairy Barn Has Moveable Floor

|

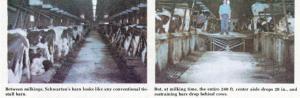

The barn's Red Wing, Minn. owner, Merle Schwartau, designed the unique barn with three goals in mind - overall expansion. increased production and saving his back. He and his 19-year-old twin sons. David and Daniel, think they've accomplished all three with their "break - through" design that has the entire 240-ft. long center alley lowering 28-in. at milking time, opening a series of Milker's Nooks between stalls for easy access.

"Ten years ago, we began working on a design that would let us stand up and milk in a tie-stall barn - for the cows' good as well as our own," explains Schwartau. "This barn, with its moveable floor and Milker's Nooks. is the answer. It gives us most of the advantages of a stall barn and parlor combined."

Those advantages mean cleaner cows, easy "stand-up" access to cows when milking, less milk-line problems. individual feeding, easier cleaning and fast milking. It takes two men 90 minutes with six units to milk 92 cows.

"They say you can milk 80 cows per hour in the new parlors, but that's if the cows are clean. You can end up spending as much time cleaning them as milking. In this barn, cows stay cleaner." Schwartau told FARM SH0W'.

The 8-ft. wide center alley is actually a suspended steel floor mounted on a metal frame. It's split into two 120-ft. sections which are raised and lowered 28-in. by hydraulic cylinders. At milking time, the Schwartaus turn on the 10-hp hydraulic pump and, in about 3 min., the floor has dropped away.

There's a Milker's Nook between every two cows - a 2 by 2 ft. cut-out that's at the level of the now-lowered alley and covered by a hinged steel cover. The operator simply lifts the cover and steps into each nook where he's in perfect position to milk.

Milk and vacuum lines run under the stalls through a 12-in PVC pipe that runs directly beneath the cows' rear legs and is cut out at each Milker's Nook for the milker hookup. The floor and milk line slope (11/z in. per 10 ft.) 36 in. end to end toward the miIkroom.

Manure falls through 14 in. wide grates at either side of the alley to gutters in the cement floor below. A conventional gutter cleaner moves manure from there to a piston pump. which pushes it to an outside storage basin.

The Schwartaus designed a system of restraining bars that lower behind the cows during milking to prevent them from stepping off the rear of their stalls. Bars suspended by cables from the ceiling are raised or lowered by two 1; 2 hp. electric winches.

When milking's over, the Schwartaus put the covers back over the Milker's Nooks, flip the switch to bring the alley back up, raise the restraining bars and, once again, their barn looks like any other conventional tie-stall barn.

Maintenance on their new-style barn is expected to be minimal. The floor lifts on an uncomplicated hinged frame, moving as far lengthwise as up. Access is good through the grates or Milker's Nooks when repairs are needed.

"We can give cows more individual care in this barn. We milked for 20 years in a parlor but there was too much mastitis and I hated the dirty hooves, legs and udders that went with the free stalls," says Schwartau.

Agromatic Equipment, Fond du Lac, Wis., and Voth and Larsen Industries, a local construction firm, gave design and construction help on the barn, which took nearly a year to build. Agromatic plans to market the hydraulic floor and Milker's Nook equipment under license with Schwartau.

The barn cost Schwartau around $400 a stall, or close to $40,000. A commercial version of the new-style dairy barn is expected to be on the market sometime next year.

For more information, contact: FARM SHOW Followup, Merle Schwartau, Route 4, Red Wing, Minn. 55066 (ph 612 388-2010).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.