1978 - Volume #2, Issue #6, Page #27

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

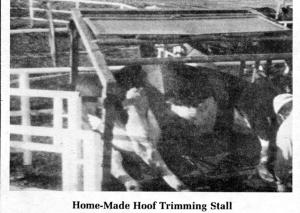

Home-Made Hoof Trimming Stall

|

The sheet metal stall is basically adapted from a feed wagon box. The foundation is anchored in concrete and the stall is moved by the hydraulic system of a tractor.

"We put ours together four years ago out of sheet metal, angle iron, pipe and cable for about $200," Santos told FARM SHOW.

To do hoof trimming, the cow is moved into the stall and two web belts are tightened underneath her belly. Four chains hold each leg in place. Then, the tractor's hydraulic system slowly tips the stall on its side, exposing the feet for trimming. Santos says a complete trimming job takes 15-30 min. per cow, depending on the treatment required.

After trimming, the hydraulic system tips the stall back to an upright position, the straps are released and the cow walks out.

The Santos herd of 375 milk cows is in frequent need of hoof trimming, or treatment of foot problems. With his own trimming stall, Santos can do the job whenever it's needed rather than waiting for a portable trimmer to become available. He says he uses his trimming stall about 30 times a year.

For more details, contact; FARM SHOW Followup, John Santos, 4363 Ave. 232, Tulare, Cal. 93274 (ph 209-686-6011).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.