1977 - Volume #1, Issue #1, Page #07

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

All-Hydraulic Crosscut Unloader For Silos

|

"We're just now getting our marketing program underway," reports David Hanson, executive vice president of Systems Equipment and Construction Corp., Savage, Minn.

Key features of the new Englishmade unloader, called the Hoy Crosscut, include:

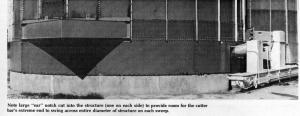

Easy servicing ù You never have to crawl inside the structure to service the unloader. Its cutting bar is the only part of the machine which goes inside the structure, with the rest positioned outside at ground level for easy accessibility for maintenance and servicing. Even the cutter bar chain, with stainless steel bushings and pins, can be examined from outside the silo during every revolution of the chain around the cutter arm. Hanson likens the machine to "a gigantic chain saw with the blade of the saw buried in a log and the prime mover in the hands of the operator." He notes that "the Hoy company, with more than 11 years' experience with the unloader in England and other European countries, proudly boasts that it has never had to dig into a silo to extract a Hoy unloader - as has often happened with conventional bottom unloaders on the market."

Hydraulic power ù Motive power for the unloader is provided hydraulically, with an electric motor, or tractor pto, powering the unit's hydraulic power pack. There are two hydraulic circuits within the separate power pack: One circuit delivers dual direction drive to the cutter bar, and the other activates two hydraulic cylinders which provide pressure to "push" the cutter arm through a maximum arc of 80 degrees. Hydraulic pressure pushes the arm into and through stored silage, cutting and conveying it to discharge outside the structure. With the separate power pack, one unit can serve several structures to help reduce costs. One permanently-positioned unit can be linked to any number of cutter arms. Or, a portable unit can be moved from one structure to the next.

High capacity ù It'll handle silage, haylage and other forages, plus a wide variety of free-flowing materials. Unloading capacity is rated at "three to four times greater than conventional bottom unloaders," says Hanson.

Two pilot installations have been operating in the U. S. for about 2 years. One is on the Steve Helgeson farm, Blanchardville, Wis., where the Hoy unloader serves a 20 by 70 ft. Harvestore. The other unloader is in a structure filled with "maltlage," a feed made of wet brewers grain, which is manufactured and marketed by Murphy Products Co.

"Retail cost of the unloader will be competitive with popular existing bottom unloaders," says Hanson. It'll adapt to already built Harvestore and similar steel storage structures, as well as to new steel, concrete or stave structures. Installation in existing steel silos takes about 12 hours and it doesn't make any difference if the structure is filled or empty.

The new-style unloader doesn't require any "bridging" of the silage or haylage stored inside the structure. On each pass, the cutter bar removes an 8 in. thick layer right off the bottom of the entire silage column. The bar sweeps from left to right, then automatically reverses its direction. As it does, direction of the cutter bar chain reverses.

Eventually, the plan is to offer a full line of feed-handling and dispensing equipment with the new unloader. For more details, contact: FARM SHOW Followup, Systems Equipment and Construction Corp., 13 West Minnesota St., Savage, Minn. 55378 (ph. 612 890-7721).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.