Tractor Mounted Bale Spears

✖  |

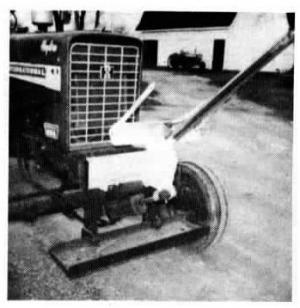

I use piston shafts from hydraulic truck hoists to make bale spears that I mount on both the front and back of my IH 656 tractor. Each spear is controlled by its own hydraulic cylinder so it can be tipped up or down independently, allowing me to haul two round bales at a time and load them onto trucks or wagons. I make the spears out of 55 in. long, 1 1/2 in. dia. hoist shafts, fashioning a point on one end. The front spear's mounting bracket is hinged, allowing the cylinder mounted beneath it to push the bale up to a 45 degree angle. The rear-mounted spear is mounted on a heavy-duty steel framework that attaches to the tractor's 3-pt. The spear is hinged on top of a vertical steel pipe, allowing the spear to raise the bale on end at a 45 degree angle and lift it 4 ft. off the ground when the 3-pt. is fully raised.

It really works slick and saves a lot of time and work. I can raise the rear-mounted bale much higher than the 3-pt. and stand bales on end. However, the front-mounted spear can raise the bale only about 16 in. off the ground so I can't use it to load bales onto a truck or trailer. I can use both spears to unload. The only disadvantage of the front-mounted spear is that when I'm on the road I have to stand so I can see ahead of me. The truck ram shaft is made with chrome-plated hardened steel so it slips in and out of the bale very easily and won't rust.

I bolted the front-mounted spear onto a 2-in. slotted pipe that's welded to a yoke equipped with a 1 1/4-in. pin that serves as a hinge. The yoke is mounted on an angle iron bracket that bolts onto the tractor's front-end weight bracket. The cylinder mounts on a bracket that bolts to the bolster ahead of the front axle. (Gene Buch, Rt. 4, Box 22, Fairfield, Iowa 52556 ph 515 472-3768)

Click here to download page story appeared in.

Click here to read entire issue

Tractor mounted bale spears HAY & FORAGE HARVESTING Bale Handling (5) 17-2-33 I use piston shafts from hydraulic truck hoists to make bale spears that I mount on both the front and back of my IH 656 tractor. Each spear is controlled by its own hydraulic cylinder so it can be tipped up or down independently, allowing me to haul two round bales at a time and load them onto trucks or wagons. I make the spears out of 55 in. long, 1 1/2 in. dia. hoist shafts, fashioning a point on one end. The front spear's mounting bracket is hinged, allowing the cylinder mounted beneath it to push the bale up to a 45 degree angle. The rear-mounted spear is mounted on a heavy-duty steel framework that attaches to the tractor's 3-pt. The spear is hinged on top of a vertical steel pipe, allowing the spear to raise the bale on end at a 45 degree angle and lift it 4 ft. off the ground when the 3-pt. is fully raised.

It really works slick and saves a lot of time and work. I can raise the rear-mounted bale much higher than the 3-pt. and stand bales on end. However, the front-mounted spear can raise the bale only about 16 in. off the ground so I can't use it to load bales onto a truck or trailer. I can use both spears to unload. The only disadvantage of the front-mounted spear is that when I'm on the road I have to stand so I can see ahead of me. The truck ram shaft is made with chrome-plated hardened steel so it slips in and out of the bale very easily and won't rust.

I bolted the front-mounted spear onto a 2-in. slotted pipe that's welded to a yoke equipped with a 1 1/4-in. pin that serves as a hinge. The yoke is mounted on an angle iron bracket that bolts onto the tractor's front-end weight bracket. The cylinder mounts on a bracket that bolts to the bolster ahead of the front axle. (Gene Buch, Rt. 4, Box 22, Fairfield, Iowa 52556 ph 515 472-3768)

To read the rest of this story, download this issue below or click

here to register with your account number.