Flipper Turns Windrow 180 degrees For Faster Drying

✖  |

Latest new development in haying is the "windrow flipper" that picks up and flips the entire swath or windrow 180? ù without rolling the hay across the ground where it could pick up dirt or rocks, and without mixing uncured hay on the bottom with cured hay on the top.

The inventor, Herman Ender Sr., Tracy, Cal., notes that the flipper, called the T-2-180, isn't designed to replace the conventional hay rake: "Here in California, it's ideal for flipping the swath after letting the hay dry a couple days, or in lighter crops to flip the double windrow after the top half has dried. Farmers in the Midwest, with shorter hay drying times, would be more likely to use the flipper after a rain to speed drying. Turning windrows with the flipper, rather than a rake, results in less leaf loss."

California farmer Stan Robertson, of Tracy has used a prototype T-2-180 for the past three years: "It does a heck of a job. Hay that used to take six to seven days to cure dries in four to five days. I also think it makes hay easier to bale since the windrows aren't rolled up tight."

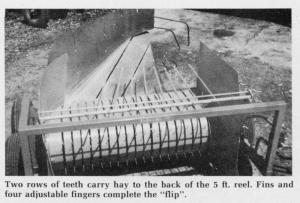

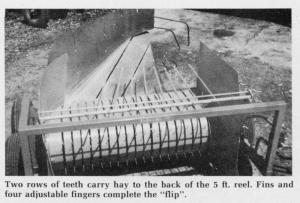

"The machine won't increase your hay production but it will minimize your losses," says Ender. Unlike conventional hay rakes, which handle hay from the top, his machine uses pick-up teeth that reach under to gently lift and convey windrows to a rear-mounted fin and four fingers which flip the windrow a full 180?. "Flipped windrows remain fluffy for increased air flow and faster curing, and the hay isn't twisted or wrapped together," Ender points out.

The machine is powered off the tractor's hydraulic system. You set a flow control valve to match tractor speed. Once set, reel speed adjusts itself to match the tractor's ground speed.

The T-2-180 sells for $5,875.

For more information, contact: FARM SHOW Followup, Herman Ender Sr., 29516 S. Bird Rd., Tracy, Cal. 95376 (ph 209 835-2535).

Click here to download page story appeared in.

Click here to read entire issue

Flipper Turns Windrow 180 degrees For Faster Drying HAY & FORAGE HARVESTING Rakes (44) 7-5-23 Latest new development in haying is the "windrow flipper" that picks up and flips the entire swath or windrow 180? ù without rolling the hay across the ground where it could pick up dirt or rocks, and without mixing uncured hay on the bottom with cured hay on the top.

The inventor, Herman Ender Sr., Tracy, Cal., notes that the flipper, called the T-2-180, isn't designed to replace the conventional hay rake: "Here in California, it's ideal for flipping the swath after letting the hay dry a couple days, or in lighter crops to flip the double windrow after the top half has dried. Farmers in the Midwest, with shorter hay drying times, would be more likely to use the flipper after a rain to speed drying. Turning windrows with the flipper, rather than a rake, results in less leaf loss."

California farmer Stan Robertson, of Tracy has used a prototype T-2-180 for the past three years: "It does a heck of a job. Hay that used to take six to seven days to cure dries in four to five days. I also think it makes hay easier to bale since the windrows aren't rolled up tight."

"The machine won't increase your hay production but it will minimize your losses," says Ender. Unlike conventional hay rakes, which handle hay from the top, his machine uses pick-up teeth that reach under to gently lift and convey windrows to a rear-mounted fin and four fingers which flip the windrow a full 180?. "Flipped windrows remain fluffy for increased air flow and faster curing, and the hay isn't twisted or wrapped together," Ender points out.

The machine is powered off the tractor's hydraulic system. You set a flow control valve to match tractor speed. Once set, reel speed adjusts itself to match the tractor's ground speed.

The T-2-180 sells for $5,875.

For more information, contact: FARM SHOW Followup, Herman Ender Sr., 29516 S. Bird Rd., Tracy, Cal. 95376 (ph 209 835-2535).

To read the rest of this story, download this issue below or click

here to register with your account number.