1983 - Volume #7, Issue #6, Page #21

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Self Loading Bucket Unloads Bag, Pit Silos

|

|

|

Jan Hoopman, manager of Hoopman Machines, manufacturer of the new feed bucket, recently crossed the U.S. visiting a Wisconsin farm where he once worked for more than a year as a hired hand to learn firsthand about North American agriculture.

"The situation is changing in the U.S., particularly for dairy farmers. Everywhere you look, farmers are trying to find cheaper ways to store silage. Some are trying big bag silage, others big bunk silos. We're excited about this development because our feeder bucket, and the other equipment our company makes, is especially suited for inexpensive and efficient handling of feed from this kind of horizontal storage," says Hoopman, noting that "Europeans have a wide choice of equipment for handling silage out of bunk or bag silos whereas comparatively little is available on the U.S. and Canadian market."

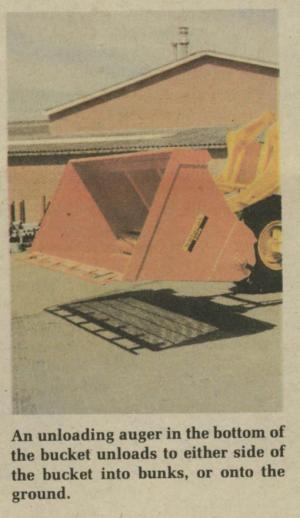

His company's new feed bucket mounts on either the tractor 3-pt. or can be mounted on the tractor loader. It pivots flat to the ground for loading, much like a conventional loader bucket, then pivots upright to carry its load. An unloading auger in the bottom of the bucket unloads feed to either side of the bucket into bunks or onto the ground.

"You can use the bucket on a small, maneuverable tractor to do the work of a tractor loader and feed wagon, or an expensive automatic feeding system," says Hoopman. "Bucket feeding is particularly attractive to the livestock farmer who is expanding and has limited space. If the animals are going to be located in more than one location, he can simply buy one side-loading bucket and easily take care of them without the major investment of a feeding system or other expensive equipment. He can design new buildings with a center feeding alley or an open side that allows for feeding with a feed bucket, as farmers in Holland do."

Hoopman says his bucket feeder is the only one in Europe that'll power-unload silage, as well as dirt, snow, and any other free flowing material. "It can be used like a tractor loader for cleaning up yards, pushing snow, and almost any other job where a loader bucket would normally be used," he notes.

A standard-size Hoopman feed bucket holds a 1,000-lb. load of silage. Buckets can be custom built bigger or smaller, and with either pto or hydraulic power. Mixer models that provide a 100% mix of silage and grain, or other additives, are also available.

The standard-size feed bucket sells for around $3,000 for two-sided unloading, controlled from the tractor seat. Buckets that unload on just one side sell for $800 less. Hoopman is looking for U.S. and Canadian distributors for the bucket, and the company's other silage handling equipment.

For information, contact: FARM SHOW Followup, Jan Hoopman, Hoopman Machines, POB 9, 7120 AA, Aalten, Holland (ph 05436-224 ext. 331).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.