1994 - Volume #18, Issue #1, Page #40

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

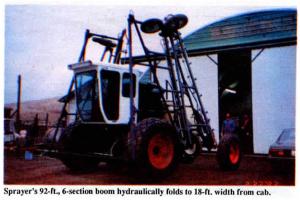

Crop Sprayer Created From Rollover Combine

|

|

Loomis's father-in-law was driving the combine on a highway when it slipped into the ditch and flipped over, landing upside down in a field. Luckily, he escaped with only bruises and scrapes but the upper half of the combine was ruined. However, the frame was undamaged.

"Financially I came out smelling like a rose," says Loomis, who made the conversion last winter. "The insurance company paid me for the value of the combine, then gave it to me because they didn't want to spend the money to haul it away. I spent only about $5,000 to convert it into a sprayer. I could have spent as much as $26,000 for an 80-ft. pull-type sprayer."

Loomis removed the cab and replaced it with a used one designed for an earlier model Gleaner combine. He stripped every-thing else down to the frame, remounting the 158 hp diesel engine in a lower, forward position. The combine still has its original hydrostatic transmission. Loomis made a steel cradle for a 650-gal. spray tank that mounts behind the engine. He used sq. steel tubing to build a 92-ft., 6-section boom that's mounted on the combine drive axle. Loomis welded lengths of 6-in. sq. steel tubing to each side of the axle, then bolted the boom to the tubing. The boom hydraulically folds to an 18-ft. width from the cab.

The boom is divided into two halves that can be individually controlled from the cab. It's supported by 6 small implement gauge wheels, one per section. "I couldn't mount the boom in place of the header because it would have been too heavy for the header mounting brackets. Also, on our steep hills the boom wouldn't have stayed parallel to the ground. On a self leveling combine, the axle is the only part of the combine that stays parallel to the ground. The nozzles are spaced 20 in. apart. Foam marker nozzles are mounted on each end of the boom. The hydraulic driven sprayer pump is controlled from the cab.

Contact: FARM SHOW Followup, Steve Loomis, Box 2, St. John, Wash. 99171 (ph 509 648-3961).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.