Turn Around Kit For Pull-Type Choppers

✖  |

"You get all the advantages of a factory-made self propelled silage chopper for about half the cost," says Charles Thor, inventor-manufacturer of the unique kit that adapts Deere's popular pull type chopper (Model 3800) for front hitching.

Instead of pulling it, you push it. And, instead of tying up a lot of money in a power unit, you use the tractor you already own to provide the power.

The converted chopper hitches in front and rides on a special dolly. The chopper is carried on its own wheels to follow ground contour independent of the tractor. The driver, as he turns the steering wheel to steer the tractor, automatically steers the front mounted chopper. For example, if the tractor wheels turn 30? to the right, the chopper dolly wheels also turn 30? to follow the exact same path.

"We've converted pull type choppers of various makes and models for front hitching, but the Deere 3800, with a two or three-row head (30 or 38 in. rows) is by far the most practical and popular," says Thor. "It'll go on most any make of tractor, whether two or four wheel drive."

Thor buys the key component parts of the chopper, such as the assembled gathering unit, cutter head and feedroller mechanism, then assembles the unit in his shop. The remaining parts (axle, steering, blower and drive mechanism) are fabricated in his shop.

"We build the blower from scratch. Because we're throwing the silage further, we've redesigned it to get the extra blast force required to throw freshly-chopped material up and over the tractor and into the trailing wagon. The revamped blower will handle any material that you can move through the vertical pipe on a tall tower silo. We drive the blower fan right off the cutter head shaft."

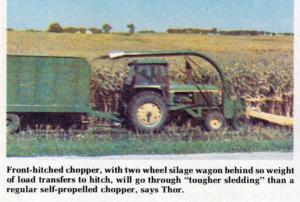

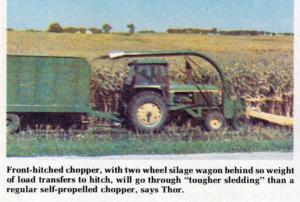

Thor notes that by buying OEM parts, as opposed to complete, fully assembled Deere pull type choppers, he doesn't end up with a lot of left over. parts that can't be used. "Our converted unit, with a 2 wheel silage wagon behind so a lot of the weight is transferred to the tractor hitch, will go through mud and other tough sledding that a regular self-propelled silage chopper can't get through. Our unit will also go over ditches and up steep banks that a factory-made unit can't handle. Another advantage in converting to self-propelled is that you don't get any down rows when opening the field."

Thor has designed a special hookup which transfers pto power through an enclosed roller chain and, from it, via a long extension shaft running alongside the tractor, to the front-hitched chopper.

Cost of the complete conversion, with a 3-row head, is right at $18,000 to $20,000. "That's about half of the going rate for a factory-made selfpropelled chopper of comparable capacity," Thor points out.

In addition to the "self propelling feature", he has developed several other inventions to streamline silage handling, including an automatic pto coupler which, used in conjunction with an automatic hitch (another of his inventions) lets the driver hitch and unhitch silage wagons without having to leave the seat of the tractor (see accompanying photo). He also has developed an automatic endgate for apron-driven forage wagons. When the apron is put in gear, the hydraulically operated opener automatically opens the endgate. It holds the endgate open momentarily after the load is off to allow the apron to completely clean out before closing.

For more details, contact: FARM SHOW Followup, Custom Made Equipment, Charles Thor, President, Box 654, Hutchinson, Minn. 55350 (ph 612 587-2380).

Click here to download page story appeared in.

Click here to read entire issue

Turn Around Kit For Pull-Type Choppers FORAGE HARVESTERS Forage Harvesters (31F) 4-1-32 "You get all the advantages of a factory-made self propelled silage chopper for about half the cost," says Charles Thor, inventor-manufacturer of the unique kit that adapts Deere's popular pull type chopper (Model 3800) for front hitching.

Instead of pulling it, you push it. And, instead of tying up a lot of money in a power unit, you use the tractor you already own to provide the power.

The converted chopper hitches in front and rides on a special dolly. The chopper is carried on its own wheels to follow ground contour independent of the tractor. The driver, as he turns the steering wheel to steer the tractor, automatically steers the front mounted chopper. For example, if the tractor wheels turn 30? to the right, the chopper dolly wheels also turn 30? to follow the exact same path.

"We've converted pull type choppers of various makes and models for front hitching, but the Deere 3800, with a two or three-row head (30 or 38 in. rows) is by far the most practical and popular," says Thor. "It'll go on most any make of tractor, whether two or four wheel drive."

Thor buys the key component parts of the chopper, such as the assembled gathering unit, cutter head and feedroller mechanism, then assembles the unit in his shop. The remaining parts (axle, steering, blower and drive mechanism) are fabricated in his shop.

"We build the blower from scratch. Because we're throwing the silage further, we've redesigned it to get the extra blast force required to throw freshly-chopped material up and over the tractor and into the trailing wagon. The revamped blower will handle any material that you can move through the vertical pipe on a tall tower silo. We drive the blower fan right off the cutter head shaft."

Thor notes that by buying OEM parts, as opposed to complete, fully assembled Deere pull type choppers, he doesn't end up with a lot of left over. parts that can't be used. "Our converted unit, with a 2 wheel silage wagon behind so a lot of the weight is transferred to the tractor hitch, will go through mud and other tough sledding that a regular self-propelled silage chopper can't get through. Our unit will also go over ditches and up steep banks that a factory-made unit can't handle. Another advantage in converting to self-propelled is that you don't get any down rows when opening the field."

Thor has designed a special hookup which transfers pto power through an enclosed roller chain and, from it, via a long extension shaft running alongside the tractor, to the front-hitched chopper.

Cost of the complete conversion, with a 3-row head, is right at $18,000 to $20,000. "That's about half of the going rate for a factory-made selfpropelled chopper of comparable capacity," Thor points out.

In addition to the "self propelling feature", he has developed several other inventions to streamline silage handling, including an automatic pto coupler which, used in conjunction with an automatic hitch (another of his inventions) lets the driver hitch and unhitch silage wagons without having to leave the seat of the tractor (see accompanying photo). He also has developed an automatic endgate for apron-driven forage wagons. When the apron is put in gear, the hydraulically operated opener automatically opens the endgate. It holds the endgate open momentarily after the load is off to allow the apron to completely clean out before closing.

For more details, contact: FARM SHOW Followup, Custom Made Equipment, Charles Thor, President, Box 654, Hutchinson, Minn. 55350 (ph 612 587-2380).

To read the rest of this story, download this issue below or click

here to register with your account number.