One Pass Ridge Making Chisel Plow,Tiller

✖  |

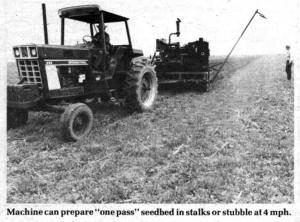

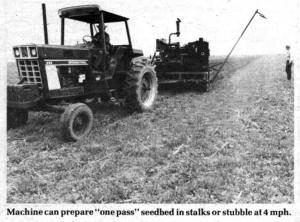

"It cuts down on passes through the field and works up the soil better than any machine on the market," says Roy Parker, vice president of N.D.T. Systems, manufacturer of a big new one-pass, ridge-making tillage machine with tiller teeth that churn up the soil at a fast 180 rpm's.

While ridge-tilling is not nearly as widespread in the Midwest as in the south, Parker says interest is growing in northern states both for irrigation, and because ridges give a more uniform seedbed that'll warm up quicker in the spring for planting.

"Based on initial tests, we feel our machine will boost production as much as 25% because of its ability to work up the soil without clods," says Parker.

The big new machine, dubbed the "Pengo Plow", consists of a row of deep-plowing chisel shanks up front, followed by the rotating tiller behind. The angled rows of tiller teeth, powered by a 300 hp diesel engine, work the soil down to a depth of 6 in. and throw the soil up into ridges adjustable from 10 to 15 in. high. When needed, you can pull packer wheels behind the machine to flatten out the ridges.

"One of the best features of the machine is that you can do a great job of incorporating pesticides and fertilizers by mounting saddle tanks on your tractor," points out Parker. "It gives tremendous incorporation not available on other machines."

It takes just 80 to 100 horsepower to handle the new plow because the tiller actually pulls itself ahead by its rotation. Parker says that, except for conditions with extreme amounts of trash, one pass with the plow on stalk or stubble ground is enough to pre-pare the seedbed. The machine can be worked through the field at speeds of 4 mph. The 6-row model will cover 80 acres a day.

So far, the company has built 11 of the new machines which are being leased out at a cost of $12 per acre, plus fuel. The company expects to work the machines on 9,000 acres this year to "get all the bugs out" before going into full production.

For more information, contact: FARM SHOW Followup, N.D.T. Systems, Box 4999, Odessa, Tex. 79760 (ph 915 362-0378 or 563-4660).

Click here to download page story appeared in.

Click here to read entire issue

One Pass Ridge Making Chisel Plow,Tiller TILLAGE EUIPMENT Chisel Plows (9) 6-4-32 "It cuts down on passes through the field and works up the soil better than any machine on the market," says Roy Parker, vice president of N.D.T. Systems, manufacturer of a big new one-pass, ridge-making tillage machine with tiller teeth that churn up the soil at a fast 180 rpm's.

While ridge-tilling is not nearly as widespread in the Midwest as in the south, Parker says interest is growing in northern states both for irrigation, and because ridges give a more uniform seedbed that'll warm up quicker in the spring for planting.

"Based on initial tests, we feel our machine will boost production as much as 25% because of its ability to work up the soil without clods," says Parker.

The big new machine, dubbed the "Pengo Plow", consists of a row of deep-plowing chisel shanks up front, followed by the rotating tiller behind. The angled rows of tiller teeth, powered by a 300 hp diesel engine, work the soil down to a depth of 6 in. and throw the soil up into ridges adjustable from 10 to 15 in. high. When needed, you can pull packer wheels behind the machine to flatten out the ridges.

"One of the best features of the machine is that you can do a great job of incorporating pesticides and fertilizers by mounting saddle tanks on your tractor," points out Parker. "It gives tremendous incorporation not available on other machines."

It takes just 80 to 100 horsepower to handle the new plow because the tiller actually pulls itself ahead by its rotation. Parker says that, except for conditions with extreme amounts of trash, one pass with the plow on stalk or stubble ground is enough to pre-pare the seedbed. The machine can be worked through the field at speeds of 4 mph. The 6-row model will cover 80 acres a day.

So far, the company has built 11 of the new machines which are being leased out at a cost of $12 per acre, plus fuel. The company expects to work the machines on 9,000 acres this year to "get all the bugs out" before going into full production.

For more information, contact: FARM SHOW Followup, N.D.T. Systems, Box 4999, Odessa, Tex. 79760 (ph 915 362-0378 or 563-4660).

To read the rest of this story, download this issue below or click

here to register with your account number.