Mower Made From Self-Propelled Swather

✖  |

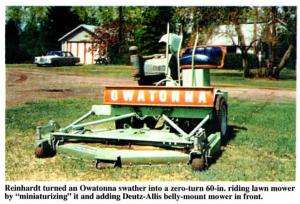

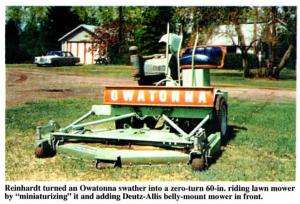

"It works as good as anything on the market and cost less than $1,000 to build," says Werner Reinhardt, Didsbury, Alberta, who turned an Owatonna self-propelled swather into a zero-turn 60-in. riding lawn mower by "miniaturizing" it.

Reinhardt paid $50 to buy the swather from a junk dealer. The mower has the swather's original Wisconsin 4-cyl. air-cooled engine and belt-driven, variable speed transmission. Reinhardt removed the swather frame and moved the drive components closer together, then used 3-in. channel iron to build a narrower frame. He put a piece of 4-in. channel iron across the front. He mounted the transmission as close as possible to the engine and replaced the original drive belt with a shorter one. He mounted a double groove pulley on a shaft between the engine and the pulley that drives the transmission to belt-drive a 90 degree gearbox which in turn belt-drives another shaft that powers the mower blades.

He replaced the swather's dual drive wheels with smaller 22.5 by 7.5 by 12-in. wheels and smaller sprockets (each wheel is chain-driven by a planetary clutch). He also replaced the original rear caster wheel with a smaller 18 by 8.5 by 8-in. caster and used 1 1/2-in. dia. steel shaft to make a new support for it. Two levers in front of the driver's seat, each connected to a planetary clutch, are used to steer the mower.

He bought a new Deutz-Allis 60-in. belly-mount mower at an auction for $550. He kept the mower's front caster wheels. However, there wasn't room for the rear caster wheels so he removed them. The mower is supported by 4 braces welded to the front of the swather frame and attached to the top of the mower with two swiveling brackets that Reinhardt made with "eye"-type hitch sockets cut off the ends of a pair of 3-pt. hitch arms. The brackets allow the deck to pivot in any direction.

"It works exactly like the original swather except that the frame is now only 3 1/2-ft. wide, narrow enough so that the wheels don't run over any uncut grass. It has the swather's zero turn radius so it's as maneuverable as anything on the market. I use a lever next to the driver's seat to control an idler pulley that engages the mower. A comparable used riding mower would cost $6,500 or more and a new one $8,000 to $9,000," says Reinhardt, who notes that he recovered the swather seat and gave the entire rig a good paint job using the swather's original colors.

Contact: FARM SHOW Followup, Werner Reinhardt, Site 15, Box 12, Rt. 1, Didsbury, Alberta, Canada T0M 0W0 (ph 403 337-2111).

Click here to download page story appeared in.

Click here to read entire issue

Mower Made From Self-Propelled Swather HAY & FORAGE HARVESTING Mowers (38) 18-5-23 "It works as good as anything on the market and cost less than $1,000 to build," says Werner Reinhardt, Didsbury, Alberta, who turned an Owatonna self-propelled swather into a zero-turn 60-in. riding lawn mower by "miniaturizing" it.

Reinhardt paid $50 to buy the swather from a junk dealer. The mower has the swather's original Wisconsin 4-cyl. air-cooled engine and belt-driven, variable speed transmission. Reinhardt removed the swather frame and moved the drive components closer together, then used 3-in. channel iron to build a narrower frame. He put a piece of 4-in. channel iron across the front. He mounted the transmission as close as possible to the engine and replaced the original drive belt with a shorter one. He mounted a double groove pulley on a shaft between the engine and the pulley that drives the transmission to belt-drive a 90 degree gearbox which in turn belt-drives another shaft that powers the mower blades.

He replaced the swather's dual drive wheels with smaller 22.5 by 7.5 by 12-in. wheels and smaller sprockets (each wheel is chain-driven by a planetary clutch). He also replaced the original rear caster wheel with a smaller 18 by 8.5 by 8-in. caster and used 1 1/2-in. dia. steel shaft to make a new support for it. Two levers in front of the driver's seat, each connected to a planetary clutch, are used to steer the mower.

He bought a new Deutz-Allis 60-in. belly-mount mower at an auction for $550. He kept the mower's front caster wheels. However, there wasn't room for the rear caster wheels so he removed them. The mower is supported by 4 braces welded to the front of the swather frame and attached to the top of the mower with two swiveling brackets that Reinhardt made with "eye"-type hitch sockets cut off the ends of a pair of 3-pt. hitch arms. The brackets allow the deck to pivot in any direction.

"It works exactly like the original swather except that the frame is now only 3 1/2-ft. wide, narrow enough so that the wheels don't run over any uncut grass. It has the swather's zero turn radius so it's as maneuverable as anything on the market. I use a lever next to the driver's seat to control an idler pulley that engages the mower. A comparable used riding mower would cost $6,500 or more and a new one $8,000 to $9,000," says Reinhardt, who notes that he recovered the swather seat and gave the entire rig a good paint job using the swather's original colors.

Contact: FARM SHOW Followup, Werner Reinhardt, Site 15, Box 12, Rt. 1, Didsbury, Alberta, Canada TOM OWO (ph 403 337-2111).

To read the rest of this story, download this issue below or click

here to register with your account number.