Combine Sickle Replaced With A Rotary Mower

✖  |

Harvest speed in soybeans is limited by the cutting ability of the cutterbar, not by the capacity of the combine. Replacing the sickle bar with a rotary mower might be the best way to boost combine through-put, say a pair of researchers looking at the idea.

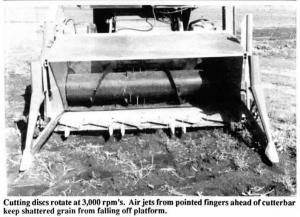

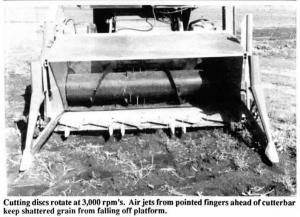

"Combines are built to handle 150 bu. corn so when they get into soybeans there's just too much capacity," says John Hummel, an ag engineer at the University of Illinois, who along with graduate student Greg Stuckey, replaced the sickle bar on a Deere 4400 combine with a Vicon 10-ft. wide rotary mower. They harvested narrow-row beans at speeds up to 7 mph with losses no greater than at 3 mph with a conventional header. "The cutting discs rotate at 3,000 rpm's and are aggressive enough to cut through even the toughest, viniest crop with ease. You can cut at whatever speed you can stay in the seat," says Hummel.

The rotary disc cutterbar was tested at speeds of 3, 5, and 7 mph. Although Hummel says it'll cut any crop at speeds as fast as you can travel, the rotary cutting method does have problems with shattering. At slower speeds, shattered beans drop onto the cutting discs rather than the platform and get thrown back onto the ground. To solve the problem, the researchers mounted air jets in "guard nozzles" positioned about 1 ft. ahead of the cutterbar. The nozzles blow jets of air back into the header, keeping crop material and shattered grain on the platform. Hummel says the addition of air works great until you get up to the highest speeds of 7 mph or more. Then the force of the air combined with the higher travel speed throws beans against the feeder auger so that they bounce back out. The solution, Hummel says, is to activate the jets at low speeds and turn them off at higher speeds. He is working on an automated control system.

The rotary cutterbar is powered off the feederhouse countershaft. The blower for the air jets mounts at one end of the header and is powered by the reel motor. It blows air into a flat chamber mounted on the floor of the platform that funnels air to the up-front jet nozzles.

One advantage of boosting cutting capacity is that combines could be fitted with narrower heads. "A narrower combine head is more effective on uneven ground, and it's much easier to transport on the road," notes Hummel.

The experiments are funded by the USDA. Equipment was donated by Deere and Vi-con. If tests prove successful this year, Hummel hopes to take the idea to a manufacturer.

Contact: FARM SHOW Followup, John Hummel, University of Illinois, 376 Ag. Eng. Bldg., 1304 W. Pennsylvania Ave., Urbana, Ill. 61801 (ph 217 333-0808).

Click here to download page story appeared in.

Click here to read entire issue

Combine sickle replaced with a rotary mower COMBINES Accessories 13-4-3 Harvest speed in soybeans is limited by the cutting ability of the cutterbar, not by the capacity of the combine. Replacing the sickle bar with a rotary mower might be the best way to boost combine through-put, say a pair of researchers looking at the idea.

"Combines are built to handle 150 bu. corn so when they get into soybeans there's just too much capacity," says John Hummel, an ag engineer at the University of Illinois, who along with graduate student Greg Stuckey, replaced the sickle bar on a Deere 4400 combine with a Vicon 10-ft. wide rotary mower. They harvested narrow-row beans at speeds up to 7 mph with losses no greater than at 3 mph with a conventional header. "The cutting discs rotate at 3,000 rpm's and are aggressive enough to cut through even the toughest, viniest crop with ease. You can cut at whatever speed you can stay in the seat," says Hummel.

The rotary disc cutterbar was tested at speeds of 3, 5, and 7 mph. Although Hummel says it'll cut any crop at speeds as fast as you can travel, the rotary cutting method does have problems with shattering. At slower speeds, shattered beans drop onto the cutting discs rather than the platform and get thrown back onto the ground. To solve the problem, the researchers mounted air jets in "guard nozzles" positioned about 1 ft. ahead of the cutterbar. The nozzles blow jets of air back into the header, keeping crop material and shattered grain on the platform. Hummel says the addition of air works great until you get up to the highest speeds of 7 mph or more. Then the force of the air combined with the higher travel speed throws beans against the feeder auger so that they bounce back out. The solution, Hummel says, is to activate the jets at low speeds and turn them off at higher speeds. He is working on an automated control system.

The rotary cutterbar is powered off the feederhouse countershaft. The blower for the air jets mounts at one end of the header and is powered by the reel motor. It blows air into a flat chamber mounted on the floor of the platform that funnels air to the up-front jet nozzles.

One advantage of boosting cutting capacity is that combines could be fitted with narrower heads. "A narrower combine head is more effective on uneven ground, and it's much easier to transport on the road," notes Hummel.

The experiments are funded by the USDA. Equipment was donated by Deere and Vi-con. If tests prove successful this year, Hummel hopes to take the idea to a manufacturer.

Contact: FARM SHOW Followup, John Hummel, University of Illinois, 376 Ag. Eng. Bldg., 1304 W. Pennsylvania Ave., Urbana, Ill. 61801 (ph 217 333-0808).

To read the rest of this story, download this issue below or click

here to register with your account number.