Plastic Plow Bottoms Outlast Steel 4 To 1

✖  |

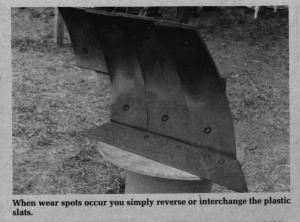

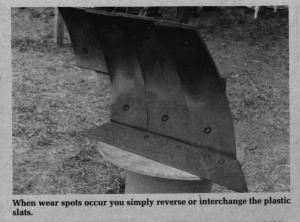

"When most plow bottoms wear out they're only worn out in one place. When our plow bottom gets a wear spot, you just interchange the slats and continue on," says Ralph Bolinger, Roann, Ind., inventor of "The Twister", a first-of-its-kind plastic slat replacement for steel bottoms.

The Twister is made with a new high-grade industrial plastic with wear characteristics that makes it as "tough as steel". Because the friction coefficient of plastic slats is 50% less than steel bottoms, and because the slats that make up the Twister can be both reversed and interchanged, Bolinger says a set will wear 4 times as long as conventional steel bottoms once the conversion is made.

To convert, the mounting shank that supports the plow bottom ù called a "frog" ù is modified with extensions and brackets that'll accommodate the plastic plow slats. Then, the slats are simply bolted into place.

A complete set includes three slatsthat run vertically down to the steel plow share at the bottom, which is left in place. The fourth piece, at rear, is simply reversible. All plastic slats are ¢ in. thick and of the same material that is now being used by companies to build car engines and other high wear parts.

"Our first prototype was made with steel slats but we've found that this new plastic material wears as well or better than steel and has less friction," says Bolinger.

The conversion bottoms are designed to fit any moldboard plow. A kit to fit 18-in. bottoms sells for $159.95 per row and a kit to fit 16-in. bottoms sells for $155.95. Both prices include about $58 for labor and hardware to convert the frogs to accept the new bottoms. Future replacement will only require the cost of the bottoms.

For more information, contact: FARM SHOW Followup, C.F.C. Distributors, Inc., Rt. 1, Roann, Ind., 46974 (ph 317 833-4231).

Click here to download page story appeared in.

Click here to read entire issue

Plastic plow bottoms outlast steel 4 to 1 TILLAGE EUIPMENT Plows 9-5-3 "When most plow bottoms wear out they're only worn out in one place. When our plow bottom gets a wear spot, you just interchange the slats and continue on," says Ralph Bolinger, Roann, Ind., inventor of "The Twister", a first-of-its-kind plastic slat replacement for steel bottoms.

The Twister is made with a new high-grade industrial plastic with wear characteristics that makes it as "tough as steel". Because the friction coefficient of plastic slats is 50% less than steel bottoms, and because the slats that make up the Twister can be both reversed and interchanged, Bolinger says a set will wear 4 times as long as conventional steel bottoms once the conversion is made.

To convert, the mounting shank that supports the plow bottom ù called a "frog" ù is modified with extensions and brackets that'll accommodate the plastic plow slats. Then, the slats are simply bolted into place.

A complete set includes three slatsthat run vertically down to the steel plow share at the bottom, which is left in place. The fourth piece, at rear, is simply reversible. All plastic slats are ¢ in. thick and of the same material that is now being used by companies to build car engines and other high wear parts.

"Our first prototype was made with steel slats but we've found that this new plastic material wears as well or better than steel and has less friction," says Bolinger.

The conversion bottoms are designed to fit any moldboard plow. A kit to fit 18-in. bottoms sells for $159.95 per row and a kit to fit 16-in. bottoms sells for $155.95. Both prices include about $58 for labor and hardware to convert the frogs to accept the new bottoms. Future replacement will only require the cost of the bottoms.

For more information, contact: FARM SHOW Followup, C.F.C. Distributors, Inc., Rt. 1, Roann, Ind., 46974 (ph 317 833-4231).

To read the rest of this story, download this issue below or click

here to register with your account number.