New Seed Treater Mounts On Auger

✖  |

"There wasn't anything on the market that would do the job," says Saskatchewan farmer Scott Norton, of Rocanville who came up with his own "no hassle" seed treater 2 years ago that'll apply any kind of dry or liquid seed treatment.

Word got around about Norton's system and researchers from The Prairie Agricultural Machinery Institute, a government funded research center, came out to take a look. They told him he ought to patent the system and bring it on the market. Norton applied for a patent and started selling units this spring.

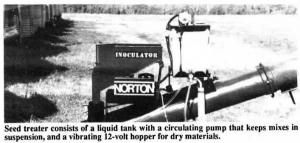

Thenew seed treater system consists of a liquid tank with a circulating pump that keeps mixes in suspension, and a vibrating 12-volt hopper for dry materials. Liquid additives or "sticking" agents are applied near the base of the auger through a hole in the top of the auger tube. The wet seed then travels 4 to 5 ft. up the auger before dry inoculant drops into the auger. Coating of the seed is completed by the mixing action of the auger as seed travels on up.

Flow rate out of the liquid applicator is controlled by either a metering valve or flow meter depending on what sticker or seed treatment you're applying. Flow rate of dry inoculants is controlled by a calibrated slide gauge positioned at the outlet end of the hopper.

Norton says the treater works great on all kinds of cereal grains as well as beans, lentils, peas, alfalfa and other crops. "Most methods farmers use now are time consuming and labor intensive. One man can operate this system and it'll mount on any 6, 7 or 8-in. dia. auger. Clamps in place with two 3/16-in. chains."

PAMI plans to publish an evaluation report on the inoculator and also worked with Norton to develop calibration charts.

Sells for $1,995 (Canadian).

For more information, contact: FARM SHOW Followup, Cinnabar Ag-Industries Ltd., Box 23, Rocanville, Sask. Canada S0A 3L0 (ph 306 645-4441).

Click here to download page story appeared in.

Click here to read entire issue

New seed treater mounts on auger GRAIN HANDLING Augers (4) 14-3-26 "There wasn't anything on the market that would do the job," says Saskatchewan farmer Scott Norton, of Rocanville who came up with his own "no hassle" seed treater 2 years ago that'll apply any kind of dry or liquid seed treatment.

Word got around about Norton's system and researchers from The Prairie Agricultural Machinery Institute, a government funded research center, came out to take a look. They told him he ought to patent the system and bring it on the market. Norton applied for a patent and started selling units this spring.

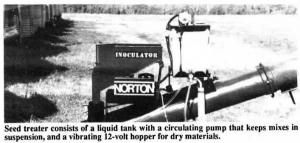

Thenew seed treater system consists of a liquid tank with a circulating pump that keeps mixes in suspension, and a vibrating 12-volt hopper for dry materials. Liquid additives or "sticking" agents are applied near the base of the auger through a hole in the top of the auger tube. The wet seed then travels 4 to 5 ft. up the auger before dry inoculant drops into the auger. Coating of the seed is completed by the mixing action of the auger as seed travels on up.

Flow rate out of the liquid applicator is controlled by either a metering valve or flow meter depending on what sticker or seed treatment you're applying. Flow rate of dry inoculants is controlled by a calibrated slide gauge positioned at the outlet end of the hopper.

Norton says the treater works great on all kinds of cereal grains as well as beans, lentils, peas, alfalfa and other crops. "Most methods farmers use now are time consuming and labor intensive. One man can operate this system and it'll mount on any 6, 7 or 8-in. dia. auger. Clamps in place with two 3/16-in. chains."

PAMI plans to publish an evaluation report on the inoculator and also worked with Norton to develop calibration charts.

Sells for $1,995 (Canadian).

For more information, contact: FARM SHOW Followup, Cinnabar Ag-Industries Ltd., Box 23, Rocanville, Sask. Canada SOA 3L0 (ph 306 645-4441).

To read the rest of this story, download this issue below or click

here to register with your account number.