If you've been thinking of heating your shop or other buildings with waste oil, or maybe rigging up a waste oil crop dryer, Robert Benjamin, Ford Benton, Mont., has a set of plans that can get you started in the right direction in building your own waste oil burner out of salvaged materials.

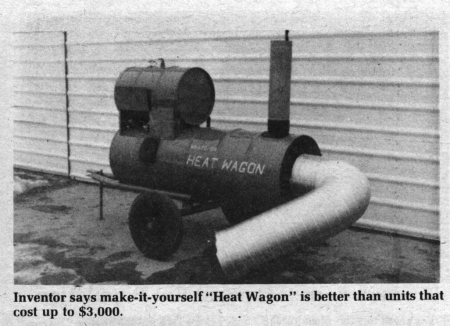

"We feel our Heat Wagon is more efficient, more trouble-free and will last longer than comparable factory-made units that cost more. Farmers handy in a workshop can build it in several days and for less than a commercial rig," says Benjamin.

The Heat wagon uses an "air atomization" burning system. "A small volume of air (about .3 cfm) from your shop air compressor is used to atomize the oil and a strip of stainless steel serves as a secondary vaporizer and flame stabilizer. Because the oil is broken up into such fine particles and mixed with air, it lights easily and burns with a bright, clean, smoke-free flame, even in cold weather. There are no fine screens or small orifices where particles in the oil might collect, causing fouling or plugging," Benjamin explains.

Only moderate preheating of the oil is required for good combustion. A 100-watt light bulb in an enclosed and insulated burner chamber serves this purpose. The Heat Wagon can deliver 150,000 btu per hour consuming 1 gal. of oil per hr.

To build the unit, you take eight 14-in. car wheels, remove the centers and weld the wheels together side by side. This forms a Iong, heavy corrugated tube which acts as a heat exchanger. Old oil drums enclose and insulate the rims. Since the unit's designed for outdoor use, no inside flues are needed. The heater can be set up on skids, or made portable by adding wheels and a hitch. By adding a small engine-driven air compressor, the unit can be completely self-contained.

The 19-page set of illustrated plans are for sale. Benjamin also sells a kit which includes many of the components that may be hard to find or build. Components may also be purchased separately.