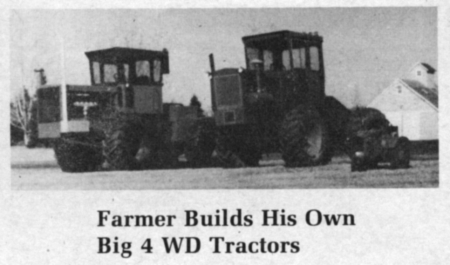

"The materials to build these cost me just 15 to 20 percent of what a comparable horsepower factory-made tractor would cost," says Cogswell, N. Dak., farmer Alfred Dahl, who builds his own big 4-WD tractors.

Dahl notes that besides the initial cost savings, his home-built tractors are built simply so they're easy to repair with ordinary handtools.

"The first 4-WD tractor I built was in 1970. It has 125 hp and is still in good shape. I started with a 4-71 Detroit diesel engine and a 5-speed Spicer transmission. I put Minneapolis Moline axles and transmissions on both the front and rear, and added 12 by 38 tires. With the 5 speeds in the MM transmission and 5 in the Spicer, I had 25 different speeds available but I only used about 4 or 5.

"I built the transfer case in my shop using MM gears, shafts and bearings. Aside from some minor machining and pressing, the tractor was totally built and assembled in my shop except for the cab, which is factory made and is air-conditioned," notes Dahl.

"My second tractor, colored prairie gold, was built using a 6-71 Detroit diesel engine. I also used MM axles both front and rear on this machine and put on 26 by 23.1 tires. This tractor has some improvements over the first, including a 10 speed Fuller transmission with all speeds being very practical.

"Besides building all of this tractor in my shop I also built the transfer case and cab. The transfer case has MM bearings but, due to the larger engine, it has heavy Caterpillar gears. The cab is rubber-mounted and insulated to reduce the noise level. It also has air-conditioning and a heater. Produces 105 hp at the drawbar and is very comfortable to run. I've had less repairs and maintenance then some factory-made tractors I've owned," says Dahl.

"The third tractor pictured is a toy. It's patterned after a 1937 Minneapolis Moline model Z. I gave it to my son for his third birthday. He's now 42. It's been passed on to the grandchildren and is still running nice."