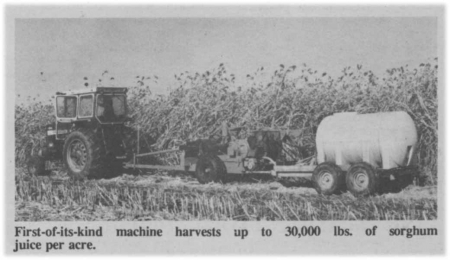

You've never seen a machine like this in-field sweet sorghum juice harvester that squeezes as much as 30,000 lbs. of juice out of an acre of sorghum right in the field for use as molasses, to make alcohol, or to sell "straight" for various industrial purposes.

Robert Scott, Mankato, Minn., designed and built the machine, by modifying a Gehl 188 8-blade forage chopper. The flywheel, gearbox and blower housing are removed. The crusher mill attaches to the back of the feeder housing and feeder rolls. The tractor pto drives the crusher rollers via a transaxle unit taken from an IH WD9 tractor. Crushing pressure on the rollers, which Scott built from scratch, varies from 75 to 100 tons, controlled by a self-contained hydraulic system that maintains pressure with a nitrogen-over-hydraulic accumulator that maintains pressure on the rolls. He pulls the machine with an IH Hydro 1026. A 600 gal. storage tank trails behind the machine. Juice content of the sweet sorghum varies from 65% to well over 70% at harvest, which can be any time from early to late fall.

"The juice can be boiled down to table grade molasses for either human or animal consumption. Alcohol producers like it because it can be fermented directly with a high yield of ethanol. There's also a demand for the product for various industrial uses. It'll produce a higher net income than corn or soybeans and is highly adaptable to the Corn Belt," says Scott, who notes that the residue can be baled and fed to livestock, or left in the field to dry and baled later for use as bedding for livestock.

"It's the only machine of its kind. Up until now this type of juice harvest has involved tremendous labor and to haul the material to a stationary crusher-extractor," says Scott, who's currently developing a production model and looking for a manufacturer.