"I needed a machine that would do a good job shredding plant and animal residue into tiny pieces and then mix it into the top 3 to 4 in. of soil," says David C. McCoy, a Fredericktown, Ohio farmer who has built the majority of the equipment he uses in his no-till, "organic" farming operation.

McCoy compares his "Spider Plow" with the way his cows chew their cud. "Cows produce nature's most perfect food by chewing and re-chewing forage into small enough pieces for the bacteria in their rumen to break it down. In the same way, this revolutionary new tillage tool renders crop and animal residue into small enough pieces so soil bacteria can convert it into a form my crops can use. This process must take place in the upper layer of soil where there's enough oxygen to speed decomposition."

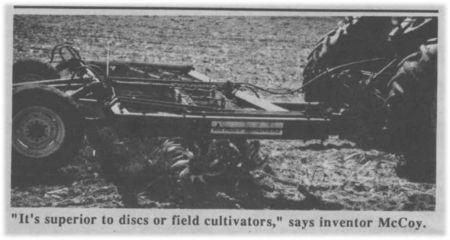

The Spider Plow gets its name from the large, 21-in. dia. spider wheels, mounted in an intermeshing pattern, that work over residue and top soil layers. McCoy says he can easily adjust the V-shaped pattern of twin gangs from slight tillage to extremely aggressive tillage by simply changing the angle of attack. "That's what makes this one of the most universal tillage tools ever built," he told FARM SHOW.

Use of the Spider Plow has eliminated two passes over cornfields and improved quality of the seedbed. "I used to chop my cornstalks and then disc them once in the fall. Then in the spring, before sowing hay or another crop, I'd disc or field cultivate twice. Now I chop the stalks in the fall and wait till spring to cross the fields once diagonally with the Spider Plow. No other tillage is needed," says McCoy, noting that the new plow would be the perfect tool for no-till farmers who occasionally want to mix accumulated soil residue into upper layers of soil. "It's superior to discs, Meld cultivators and other tillage tools because you can so easily change the angle of attack." McCoy adds that in many cases use of the Spider plow alone in the spring or fall is often enough to prepare the seedbed.

By setting the angle of attack in a less aggressive mode and precisely controlling depth of penetration with the lift wheels, McCoy says the Spider Plow can also be used for chemical incorporation, and as a pasture aeration tool. He pulls it at speeds of 6 to 7 mph with an 80 hp tractor. Effective working width is 11 ft.

The

Spider Plow has just 8 moving parts, is self-cleaning, and ground-driven. It

requires minimum horsepower to pull due to the rolling effect of the spider

wheels. McCoy built the machine on the frame of a 12-ft. Allis Chalmers 600 no-till

planter with 28 spider wheels from Lilliston. He used standards and standard

frames from a Deere 11 1/2-ft. disc. The only routine maintenance required is grease for the

16 grease zerks and the only adjustment is for the angle of attack, which

changes quickly with one lever.

McCoy has been negotiating with manufacturers to bring the machine to market.