Latest new way to move conventional hay bales into storage is the revolutionary Aug-A-Bale system that uses two 5-1/2 in. dia. metal augers instead of chains to propel bales up and into the barn.

Inventors Bob Checkley and Rudy Neilsen, of Arthur, Ont., have applied for a patent and are marketing their new system through Rubob Mfg.

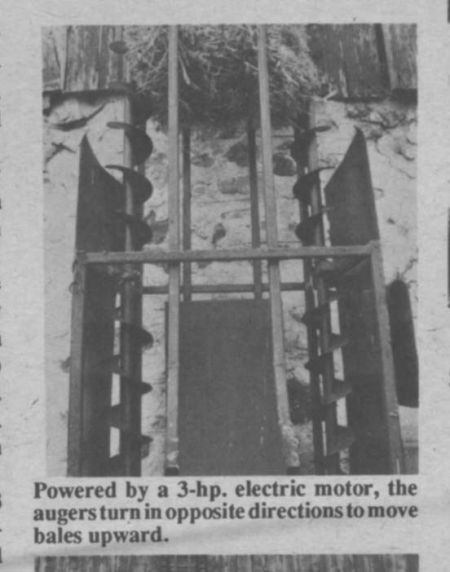

The revolutionary new Aug-A-Bale conveyor is positioned vertically directly parallel to the barn wall. It consists of a short hinged conveyor (3, 5 or 10 ft. long) connected to a vertical cage built of 1 in. sq. tubing. The cage encloses a pair of 5 1/2-in. dia. steel augers running parallel to each other and spaced 24 in. apart.

The augers, powered by a ground-level 3 hp electric motor, rotate in opposite directions, grabbing the edges of each-bale and moving it to the top of the cage. There, a bar deflects it into the opening at the top of the barn. You can move bales farther into the barn with a "skeleton" elevator, or by hand.

Checkley and Neilsen built their first prototype last year and used it to move over 10,000 bales into storage. "The vertical chain elevators we'd previously used gave us problems. We wanted something that was virtually maintenance free, which led us to develop this chainless auger system. The short input conveyor can be pivoted up or down, making it easy to load bales from a wagon or truck. Irregular-shaped bales are no problem because the augers straighten them out," says Checkley.

"We can supply augers to any length, depending on your barn's height. Standard sizes are 3, 5 and 10 ft. long conveyors, and augers up to 70 ft. long."