"There's never been anything like it on the market. Interest has been tremendous from local farmers and our four prototype units have worked perfectly," says Deere dealer Loras Gravel, Dyersville, Iowa, about the first-of-its-kind baler-mounted stalk chopper he and Michael Trenkamp, also of Dyersville, invented and now manufacture.

"When we got involved in the local Deere dealership several years ago, one of the first things we noticed was that when people baled cornstalks it took a long time because they had to make three trips over the field -- to chop, rake and bale -- and they almost always broke a lot of pickup teeth and stripper plates. We decided to try to improve the process and built our first prototype baler-mounted chopper a year ago," says Gravel. "The first prototype didn't work the way we wanted it to but we could see that the basic idea was good. We redesigned the unit and then built four prototypes and gave three of them to farmers. They worked great."

The farmers made from 250 to more than 2,000 bales with the units. "Except for minor changes, our first production units will be nearly identical to the prototypes. We think we have a strong, dependable design that's simple and easy to service. It's got a heavy-duty shaft, 3 bearings, and reversible flail chopper knives," says Gravel.

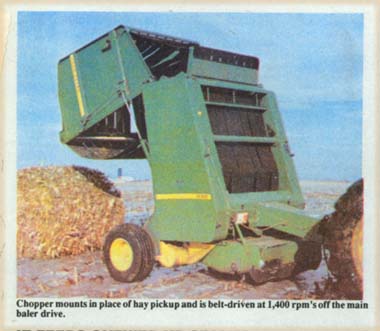

The chopper is chain-driven off the main baler drive. The chain drives a sprocket attached to a belt pulley that drives a smaller belt pulley, which gears the shaft up to operating speed of 1,400 rpm's. To install, the baler hold-down tines are removed and three brackets must be welded to the baler. The only operating adjustment that must be made on the baler is to reduce the density setting.

"The bales are heavy and very dense. Farmers were impressed with the quality of the bedding -- the chopper chops stalks in 6 to 8-in. lengths -- and they liked the fact that the bales are neat and easy to handle corn-pared to stalks gathered in 'stack makers' they'd used in the past. Our chopped stalks make excellent bedding and good feed for dry and stock cows. One farmer injected the bales with molasses before feeding them," says Gravel.

The chopper unit can be easily removed to convert the baler back to baling hay. Gravel says one sign of how well the chopper works is that all three farmers who were given prototype units to test have purchased the add-on chopper units. "One farmer has already pre-sold 1,500 bales for next year to neighbors who tried his stalk bales this year.

At this time the chopper fits Deere's 530 round baler but the company plans to fit other makes and models in the near future. The chopper is the width of the bale chamber, wide enough to chop two rows of cornstalks at a time. Gravel says the chopper works best on standing stalks since it works down to within 2 in. of the ground. Farmers who've used the unit chopped the rows of stalks left standing by the combine and skipped the rows that were flattened. He says many farmers want to be able to pick up down stalks, however, so the company is experimenting with different shaped flails that would create more vacuum, sucking stalks up into the machine.