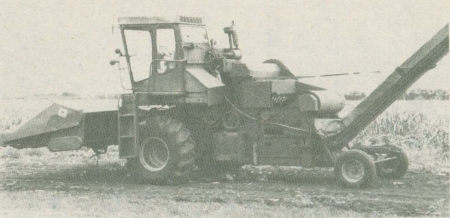

Old combines make great corn pickers, say Floyd Miller and sons Conrad and Elwood, White Pigeon, Mich., who built an inexpensive "combine picker" by removing the threshing system from a 1970 Deere 6600 6-row combine and replacing it with a New Idea 837 husking bed.

The Millers lengthened the combine frame 2 ft. to install the husking bed. A special-built conveyor throat transports ear corn from the feederhouse to the husking bed.

"It's

a nice, neat unit," says Floyd, who grows 600 acres of seed corn. "We

had been using three New Idea Uni-Harvesters but we got tired of repairing

them. Our 'combine picker' is dependable and easy to work on. We used a Deere

6600 combine because the front-mounted engine doesn't disturb the drive train

of the husking bed. The engine sits on top out in the open where it's easy to

work on, whereas the engine on the Uni-Harvester is next to the husking bed and

is difficult to reach. Another benefit is that we can speed up the throat,

husking bed, and cleaning fans right from the cab. The husking bed can't be

sped up at all when it's mounted on a Uni-Harvester. Our 'combine picker'

also cost far less than the cost of a new Uni-Harvester."

The Millers dump corn from the "combine husker" into six 14-ft. long hydraulic-hoist dump wagons which they built from junked-out self-unload forage wagons. The wagons rear-unload corn into a home-built drive-over dump hopper that delivers corn to a 30-in. wide elevator that fills semi-trucks in the field. The elevator, drive-over dump, and hydraulic-hoist wagons are all operated by the tractor which the Millers use to move the system from field to field.