Two Kansas wheat farmers licked their wet field woes at harvest and at planting by building a self-propelled grain cart out of old combines.

"A lot of times at harvest it's too wet to get a truck into the field, so you have to go to the edge of the field with the combine to unload," notes Harold Depenbusch, Columbus, Kan. "This cart lets us go to the combine no matter what the conditions."

Likewise, the grain cart is equally handy for getting into the field with seed during wet planting seasons, he adds.

"It frees up my tractors. You don't have to wait to hook stuff up, you can just go," Depenbusch says.

He and son, Craig, built the 150 bu. grain cart during the winter of 1993.

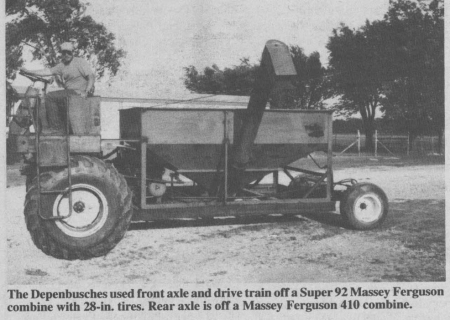

They used the front axle and drive train off a Super 92 Massey Ferguson combine with 28-in. tires. They picked it up from a salvage yard on the cheap. "We took all the separator parts off the Super 92," Depenbusch explains. 'We sawed off the whole back part of the frame right behind the engine."

The Depenbusches next built a 7-ft. wide by 10-ft. long frame out of 6 in. channel iron and mounted it on the Super 92's axle. For the cart's rear axle, they used a rear axle off a burned out 410 Massey Ferguson combine. The cart's rear tires are old airplane tires.

Once the chassis, which has ground clearance of 15 to 18 in., was finished, they found they had to modify the Super 92's cooling system. "We had to relocate the combine's radiator because it wasn't mounted accessibly," he says. "So we moved it to the front right corner of the grain tank."

The cart's 7 by 10-ft. grain tank is an old center-dump custom-built grain box the Depenbusches picked up. It's bolted to the frame and braced with 2 in. angle iron front, sides and rear.

The men fitted the tank with an unloading auger, driven by two combine belts and a jack shaft, which folds to the rear when not in use. So besides dumping out the bottom of the cart, they can also auger grain -- or seed -- out the side.