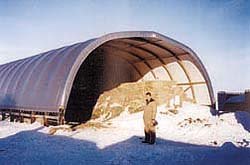

When Alfred Enns went looking for a low-cost "hoop" building, he was surprised at the prices he was quoted. He didn't feel he could justify the price of a 40 by 100-ft. shed.

"I also didn't like that the frames were made out of steel because when I looked around my farm, I realized that the oldest structures we have all are made with wood frames. So we decided to make our own buildings," says Enns, who came up with a process to make laminated wood "hoops" which he then covers with canvas like any other "hoop" buildings. He has put up four of the buildings on his own farm and more than 40 units on neighboring farms.

"The difference between our buildings and other ones on the market is that wood is cheaper than steel. The beams are also 8 in. deep so you can insulate the building, if desired. And down the road, if you decide you want a more permanent structure, having a wood frame makes it much easier to replace the canvas cover with wood or metal siding," says Enns.

On his own farm, Enns uses one building to house cattle, one for calves, another to store bales, and another for machinery.

"These buildings have a tremendous snow load rating of 41 lbs. Sizes available are 30, 36, 38, 40, 44 and 50-ft. wide by any length. Our target market is farm families like our own who are looking to hoop structures because of their affordability and quick construction. With our buildings, if you decide to update them later by enclosing them with solid sides, you can do it," says Enns.