When Lloyd Kendall established a homestead property near Prairie River, Sask., in 1935, he spent countless hours riding a J.I. Case Steam Traction Engine with a breaking plow behind it.

"I always said I'd never worked so hard for nothing as I did that summer with the breaking plow," he says. "We used that steam engine one summer to break the sod so we could farm it the next year. Then for three years we used it to run a sawmill. We finally quit using it in 1938 or 1939, when we found we could operate a gasoline tractor cheaper and with less labor. The steam engine sat around for a few years and I finally sold it for scrap."

"I've been terribly sorry a lot of times since then that I didn't save that traction engine, and I always said if I lived long enough and was able, I'd make a working model of it," he says.

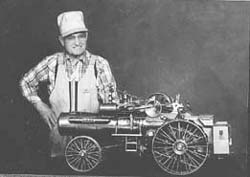

Now nearly 85 years old, Kendall has finally completed a detailed model. With the exception of some bolts and small valves, he made all of the parts himself out of scrap iron, using a lathe and mill. He wanted to buy the gears for it, but couldn't find the right sizes. Undaunted, he went to the library, read up on making gears and went home and made what he needed. He made the governor too, and, "it works fine," he says. He even made a working water pump for filling the tank.

"I only had photos and my memory to work from, so it may not be exactly to scale," he admits. "But people I've talked with who had experience with these engines -- and there aren't many of us left -- say it's authentic."

While his machine has everything it needs to actually run on steam, Kendall put a valve on the pressure tank so he can charge it up from an air compressor. "Firing it up would be too dirty. Air pressure makes it work fine," he says.

Kendall worked on the engine in his spare time over a five-year period. He says he has no idea how much time actually went into it. Out-of pocket expense was minimal.